Vanquish

Member

- Joined

- Jan 8, 2014

- Messages

- 55

Hey guys, I just got my first Festool today and I was super excited. The fit and finish is excellent, but I was pretty surprised when I turned it. It sounded, vibrated and cut like a $30 Harbor Freight saw with a bad bearing. I read online that the noise on start up is normal, but didn't see anything about it being constant before and while cutting. It's so loud that you can feel it vibrating up through the handle.

If you adjust the speed dial, you can find a few spots where it briefly starts to sound like a normal saw. The grinding is just as loud, but more intermittent. Like silent for a second, then loud for two, silent for half a second, loud for 3 etc. Sounds like a bad bearing with no grease.

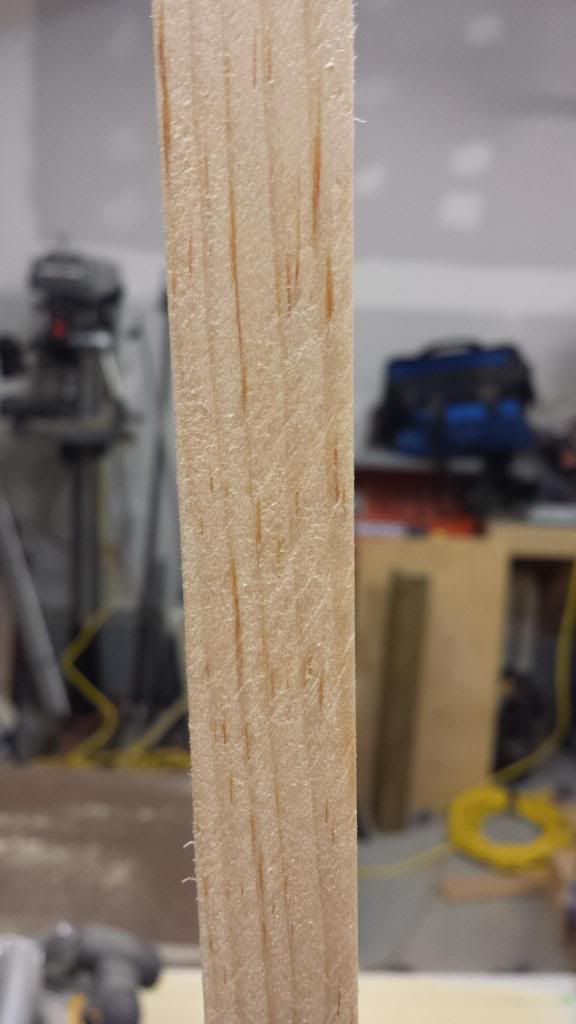

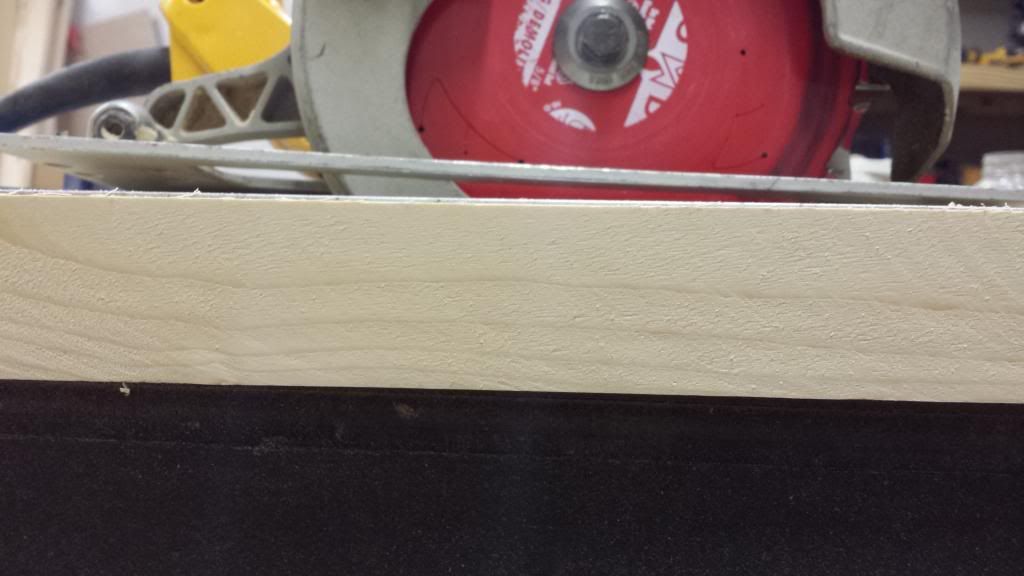

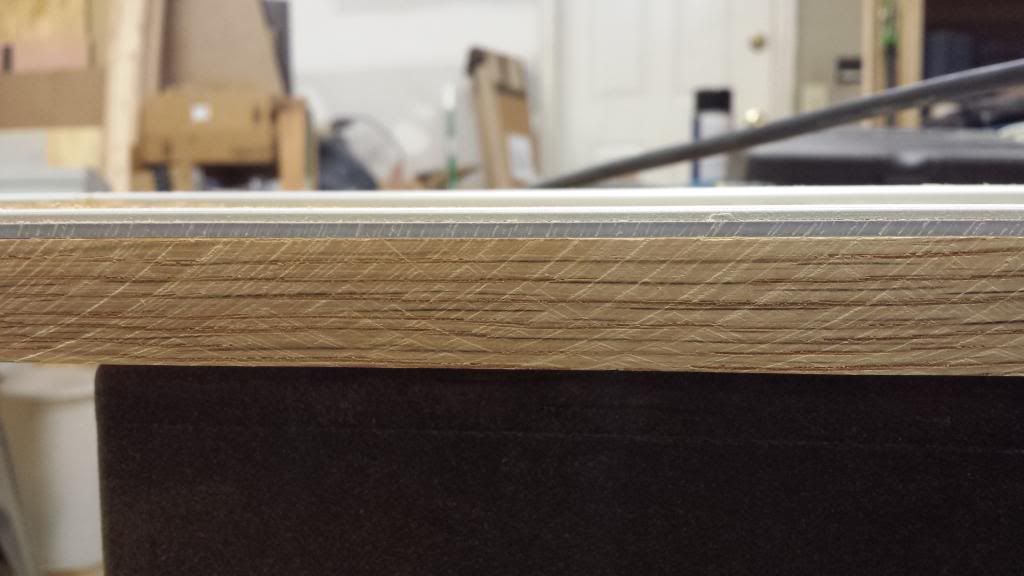

But the sound issue aside, the cuts look terrible IMO. Especially for a 48 tooth blade. Does this look normal? My fingernail catches on the blade marks it so bad. This was just in regular pine, one 3/4" and the other 1 1/2" thick. I made the same cut with my battery circle saw with a 24 tooth framing blade just to see how it compared and to be honest, I think the DeWalt cut as good, if not better. And my regular circle saw definitely cuts better than the TS 55. Not at all what I was expecting from a nearly $600 saw. :-\

Is the sound and cut quality normal, or is mine defective? I'm probably going to box it back up when I get back home tomorrow, the question is should I ask for a refund or replacement?

Here's the pictures:

Edit: looks like a can't post pictures yet.

If you adjust the speed dial, you can find a few spots where it briefly starts to sound like a normal saw. The grinding is just as loud, but more intermittent. Like silent for a second, then loud for two, silent for half a second, loud for 3 etc. Sounds like a bad bearing with no grease.

But the sound issue aside, the cuts look terrible IMO. Especially for a 48 tooth blade. Does this look normal? My fingernail catches on the blade marks it so bad. This was just in regular pine, one 3/4" and the other 1 1/2" thick. I made the same cut with my battery circle saw with a 24 tooth framing blade just to see how it compared and to be honest, I think the DeWalt cut as good, if not better. And my regular circle saw definitely cuts better than the TS 55. Not at all what I was expecting from a nearly $600 saw. :-\

Is the sound and cut quality normal, or is mine defective? I'm probably going to box it back up when I get back home tomorrow, the question is should I ask for a refund or replacement?

Here's the pictures:

Edit: looks like a can't post pictures yet.