I’m a hobbyist / maker. During making many fitted units using sheet goods I wanted a better way to secure the Festool guide rail to sheet goods including melamine, plywood, MDF and even sheets of acrylic. Some of these surfaces are slick and the guide rail can tend to slip, not good when you are cutting frameless cupboard doors perfectly square from sheets of MFMDF costing upwards of £150/$200. I wanted a quick easy way to clamp the guide rail while I made the cut without using traditional clamps that require access to the underside of the sheet and can often cause the rail to slip when you apply pressure. I designed some vacuum clamping pods that connect to a vacuum pump (not a dust extractor / vacuum cleaner) and then just simply drop into the rail and use a ¼ turn of a valve to apply and release the pressure quickly.

I’ve now used these for over a year on various project and they’ve gone through a few design iterations. After showing some woodworking friends they liked the idea encouraged me to make a few.

I’ve just made my first production run and have a limited number of sets available. During design and development, I took the decision that they should be built from high-quality components, so all the pneumatics connectors are Festo and they are engineered from POM engineering plastic which is durable but also forgiving enough not to damage the delicate surfaces.

I’ve attached a few pictures at the bottom of the post showing them in use. And I’ve also put a couple of YouTube videos online:

They are listed for sale on e-bay UK (with ebay international shipping enabled):

https://www.ebay.co.uk/itm/114077757491

https://www.ebay.co.uk/itm/114077879077 incl KD4-CK-6 connector suitable for VAC-SYS

Any questions just drop me a PM.

---

Guide Rail Vacuum Clamp System (VCS-R) for Festool® guide rail tracks

What is it?

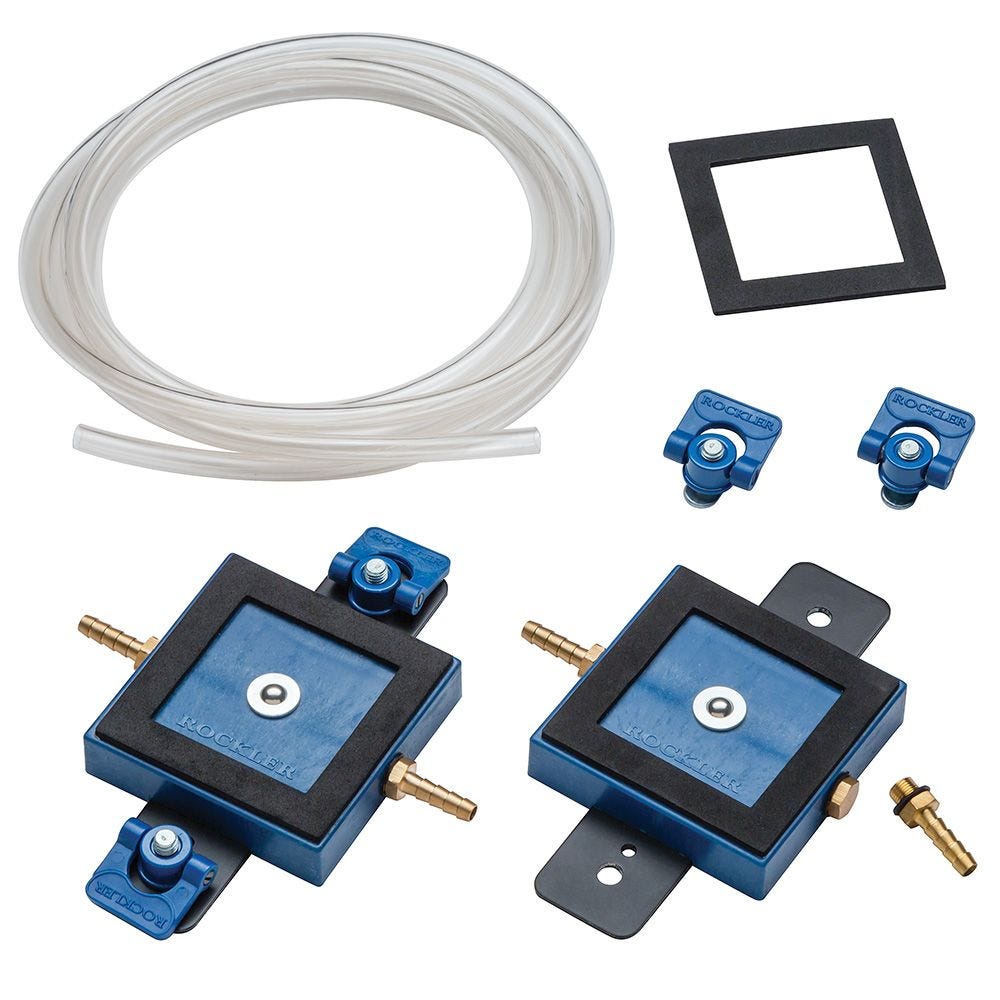

A high-quality accessory designed to firmly clamp your Festool guide rail to MDF*, Plywood, Laminate, Acrylic with the use of a vacuum pump. CNC machined from POM engineering plastic with push fit Festo pneumatic connectors.

Benefits

• Improve safety. No more trying to hold down the rail while pushing the saw along!

• Compatible with Festool® and similar guide rails

• Quick ‘no tool required’ attachment and removal.

• Speed up your workflow and save time. No more fiddling with clamps.

• Works without access to the underside of the material, ideal for breaking down sheets flat on the bench / floor.

• Optional secure mounting for use even on vertical surfaces.

• Unlike clamps it doesn’t shift the rail position when clamping force is applied.

• Works with the TSO Guide Rail Square and Parallel Guide System. No rail slippage even on long cuts.

How do I use it?

Align the rail to your cut mark. Place a couple of VCS-R modules in the groove of the rail. Turn the valve a quarter turn. Make the cut. Afterwards, turn the valve quarter turn to release the vacuum pressure. Perfect cuts every time!

What else do I need?

You need a vacuum clamping pump such as the Festool VAC-SYS or another system such as VacuPress. We can supply a Festo KD4 connection at extra cost to connect to the Festool VAC-SYS pump. For other systems you will need an adaptor from 8mm O.D tubing to your system. You also need a Festool or similar guide rail.

*Due to the porous nature of MDF vacuum pressure may be reduced but in testing there was still enough suction down to 9mm MDF to hold a guide rail secure enough to make a cut.

I’ve now used these for over a year on various project and they’ve gone through a few design iterations. After showing some woodworking friends they liked the idea encouraged me to make a few.

I’ve just made my first production run and have a limited number of sets available. During design and development, I took the decision that they should be built from high-quality components, so all the pneumatics connectors are Festo and they are engineered from POM engineering plastic which is durable but also forgiving enough not to damage the delicate surfaces.

I’ve attached a few pictures at the bottom of the post showing them in use. And I’ve also put a couple of YouTube videos online:

They are listed for sale on e-bay UK (with ebay international shipping enabled):

https://www.ebay.co.uk/itm/114077757491

https://www.ebay.co.uk/itm/114077879077 incl KD4-CK-6 connector suitable for VAC-SYS

Any questions just drop me a PM.

---

Guide Rail Vacuum Clamp System (VCS-R) for Festool® guide rail tracks

What is it?

A high-quality accessory designed to firmly clamp your Festool guide rail to MDF*, Plywood, Laminate, Acrylic with the use of a vacuum pump. CNC machined from POM engineering plastic with push fit Festo pneumatic connectors.

Benefits

• Improve safety. No more trying to hold down the rail while pushing the saw along!

• Compatible with Festool® and similar guide rails

• Quick ‘no tool required’ attachment and removal.

• Speed up your workflow and save time. No more fiddling with clamps.

• Works without access to the underside of the material, ideal for breaking down sheets flat on the bench / floor.

• Optional secure mounting for use even on vertical surfaces.

• Unlike clamps it doesn’t shift the rail position when clamping force is applied.

• Works with the TSO Guide Rail Square and Parallel Guide System. No rail slippage even on long cuts.

How do I use it?

Align the rail to your cut mark. Place a couple of VCS-R modules in the groove of the rail. Turn the valve a quarter turn. Make the cut. Afterwards, turn the valve quarter turn to release the vacuum pressure. Perfect cuts every time!

What else do I need?

You need a vacuum clamping pump such as the Festool VAC-SYS or another system such as VacuPress. We can supply a Festo KD4 connection at extra cost to connect to the Festool VAC-SYS pump. For other systems you will need an adaptor from 8mm O.D tubing to your system. You also need a Festool or similar guide rail.

*Due to the porous nature of MDF vacuum pressure may be reduced but in testing there was still enough suction down to 9mm MDF to hold a guide rail secure enough to make a cut.