I'm new to the board so I apologize if this has been covered before. Today, when I tried to switch to a wider mortise, I could not turn the knob on my domino. After many tries it finally moved, but will not return to the normal operating setting. Has anyone else encountered this problem? Chalky

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problem with domino

- Thread starter chalky

- Start date

Forrest Anderson

Member

- Joined

- Jan 23, 2007

- Messages

- 1,072

chalky said:I'm new to the board so I apologize if this has been covered before. Today, when I tried to switch to a wider mortise, I could not turn the knob on my domino. After many tries it finally moved, but will not return to the normal operating setting. Has anyone else encountered this problem? Chalky

It may sound a bit strange, but you should change settings when the Domino is running, not when it's switched off. It's like changing gears in a car with a manual gearbox (stick shift). Try doing that, and it should slip between the three settings easily.

It's covered on page 4 of the Festool manual, which says:

--------------

Setting dowel-hole width

Reliable setting of the dowel-hole width with the rotary switch (1.2) is only possible with the machine running!

The following dowel-hole settings are possible (Fig. 8):

- 13 mm + jointer bit diameter

- 19 mm + jointer bit diameter

- 23 mm + jointer bit diameter

-----------------

It's also mentioned on page 8 of Rick Christopherson's Supplemental Manual, whilst Jerry Work's Getting the Most from the Festool Domino is also an excellent read.

Forrest

Hi Chalky & welcome.

Forrest is right. When i first got my Donimo I had the same problem & phoned my rep to say it must be faulty. The answer, try it when switched on. Worked perfectly. Same old story, read the manual. I guess its a man thing, we don't need instructions, do we ?

Woodguy

Forrest is right. When i first got my Donimo I had the same problem & phoned my rep to say it must be faulty. The answer, try it when switched on. Worked perfectly. Same old story, read the manual. I guess its a man thing, we don't need instructions, do we ?

Woodguy

- Joined

- Jan 22, 2007

- Messages

- 8,426

Changing the mortising width knob without the machine running can actually damage the gears. Like Forrest said, this is in the manual.

http://www.festoolusa.com/media/pdf/475005_003_df500_usa_nl.pdf

Page 10 states:

http://www.festoolusa.com/media/pdf/475005_003_df500_usa_nl.pdf

Page 10 states:

CAUTION! Failure to follow the notes below may result in damage to the tool.

- Never force the dial to turn.

- Rotate the adjustment dial only when the motor is running.

- Never rotate the dial during a plunging operation. This can bend or break the mortising bit, and can also damage the machine.

jonny round boy

Member

- Joined

- Jul 21, 2007

- Messages

- 3,227

I don't know why, but I had read the manual as "only change the width setting when the machine is NOT running". I read Rick's supplemental manual too, but never picked up on my error.

I did have trouble switching it on a couple of occasions - obviously the gears weren't aligned - but found that switching the machine on for a just a second often fixed that, as it changed the alignment & allowed the gears to mesh correctly. I never needed to force it.

To me, switching it whilst running seems wrong. Like changing gear in a car without depressing the clutch! Maybe that preconception is what caused me to read the manual wrong. I don't know. But I will get my domino out tomorrow & try it running!

I did have trouble switching it on a couple of occasions - obviously the gears weren't aligned - but found that switching the machine on for a just a second often fixed that, as it changed the alignment & allowed the gears to mesh correctly. I never needed to force it.

To me, switching it whilst running seems wrong. Like changing gear in a car without depressing the clutch! Maybe that preconception is what caused me to read the manual wrong. I don't know. But I will get my domino out tomorrow & try it running!

JohnDistai

Member

- Joined

- Jan 2, 2010

- Messages

- 216

I'm glad you guys brought this up. It really seems counter-intuitive to change the width while running.

- Joined

- Jan 22, 2007

- Messages

- 1,641

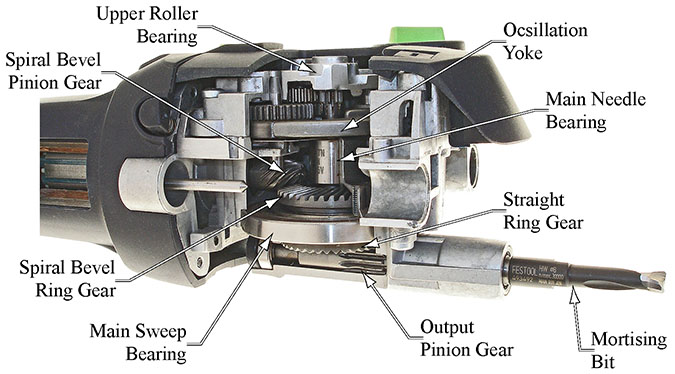

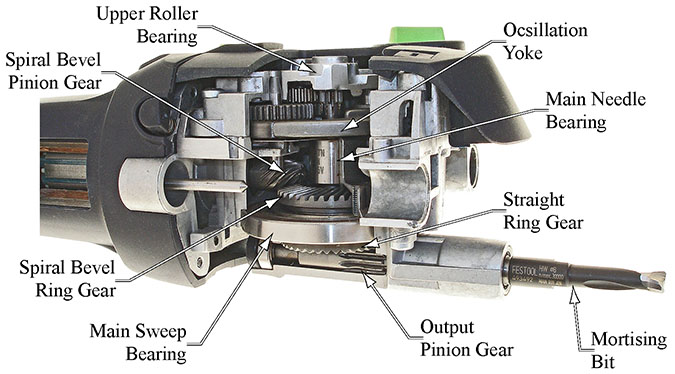

It isn't so much that real damage will occur either way, but the gears will mesh easier when the tool is running. If you CAN rotate the dial when the tool is not running, then all is fine and the gears are meshing in their new position. However, if the gears do not mesh easily, of course, you can cause damage if you try to force the dial to turn when the gears are not in position to mesh. The mechanism to alter the width of the sweep is very complex, and the gears and yoke need to be in the right position(s).

JohnDistai

Member

- Joined

- Jan 2, 2010

- Messages

- 216

I think we may have an issue at this point. On one hand we have Shane, who has identified himself as a Festool employee stating that it is possible to damage the gears if switching while off. On the other hand, we have Rick who may or may not be a Festool employee stating that it will not damage the gears if we switch them while the Domino is off. I would hate for someone to get into the position of following one person's advice and have it be wrong, damage the tool, and not have it covered in the warranty. Who's advice is correct? Also, this demonstrates the importance of a consistent message.

Of course! Who would do such a dumb thing! Not me, that's for sure. I'd never change that width setting unless the motor is GOOD AND ON! No way, not in a million years. Not gonna happen.

Actually I've been doing the right thing almost from the start but not because it's in the manual. I found out in the first few of weeks that mine slipped into another setting more reliably when turned on. So that's the way I've been doing it. But I thought all along until I saw this thread that it was a PROBLEM! I thought there was something wrong with my Domino. My plan was to take it in sometime before the warranty expired and have it checked out.

I think I should go back and read the manual again. And when I read it this time I'll read it. Unlike the first time I read it when I didn't read it.

If they had stamped in bold red on the cover. Secret information! Festool corporate use only! I bet I would have read it. I would have hung breathlessly on every word.

Actually I've been doing the right thing almost from the start but not because it's in the manual. I found out in the first few of weeks that mine slipped into another setting more reliably when turned on. So that's the way I've been doing it. But I thought all along until I saw this thread that it was a PROBLEM! I thought there was something wrong with my Domino. My plan was to take it in sometime before the warranty expired and have it checked out.

I think I should go back and read the manual again. And when I read it this time I'll read it. Unlike the first time I read it when I didn't read it.

If they had stamped in bold red on the cover. Secret information! Festool corporate use only! I bet I would have read it. I would have hung breathlessly on every word.

Switch settings while the tool is operating is what Festool recommends for the operation of the tool.

Brice Burrell

Member

- Joined

- Mar 13, 2007

- Messages

- 7,386

JohnDistai said:I think we may have an issue at this point. On one hand we have Shane, who has identified himself as a Festool employee stating that it is possible to damage the gears if switching while off. On the other hand, we have Rick who may or may not be a Festool employee stating that it will not damage the gears if we switch them while the Domino is off. I would hate for someone to get into the position of following one person's advice and have it be wrong, damage the tool, and not have it covered in the warranty. Who's advice is correct? Also, this demonstrates the importance of a consistent message.

John, you didn't read Rick's post very carefully. Here it is again:

Rick Christopherson said:It isn't so much that real damage will occur either way, but the gears will mesh easier when the tool is running. If you CAN rotate the dial when the tool is not running, then all is fine and the gears are meshing in their new position. However, if the gears do not mesh easily, of course, you can cause damage if you try to force the dial to turn when the gears are not in position to mesh. The mechanism to alter the width of the sweep is very complex, and the gears and yoke need to be in the right position(s).

Rick is not a Festool employee, he only writes the supplemental manuals.

- Joined

- Jan 22, 2007

- Messages

- 8,426

JohnDistai said:On one hand we have Shane, who has identified himself as a Festool employee stating that it is possible to damage the gears if switching while off. On the other hand, we have Rick who may or may not be a Festool employee stating that it will not damage the gears if we switch them while the Domino is off. .... Who's advice is correct? Also, this demonstrates the importance of a consistent message.

John, simply put: follow the instructions, and more importantly the warnings, in your owners manual. The manual states damage may occur if the width setting is changed while the machine is not running. It does not say specifically what type of damage may result but I have been told gear damage. Regardless of the type of damage which may result, it's not worth the risk of disregarding this warning. The manual should supersede any advice given by myself or others.

Rick is correct. Its impossible to damage it if its not running. The only damage that can occur is to the plastic switch itself. - (this is only my opinion)

Factory manuals arnt the be all and end all, often the stuff they say is to cover their own [insert inoffensive common term stupid auto filter blocked out] if something does go wrong. They rarely tell us what we "need "to know, thats why people like Rick are invaluable writing manuals with stuff we "do" need to know.

Factory manuals arnt the be all and end all, often the stuff they say is to cover their own [insert inoffensive common term stupid auto filter blocked out] if something does go wrong. They rarely tell us what we "need "to know, thats why people like Rick are invaluable writing manuals with stuff we "do" need to know.

JohnDistai

Member

- Joined

- Jan 2, 2010

- Messages

- 216

Brice,

I did read what Rick wrote. I was pointing out that we have conflicting advice, one from a Festool source, and one from a non-Festool source. If I did something to break the tool and then pointed to the non-Festool source as the reasoning for my actions, I don't think Festool would be obligated to cover a warranty repair.

I did read what Rick wrote. I was pointing out that we have conflicting advice, one from a Festool source, and one from a non-Festool source. If I did something to break the tool and then pointed to the non-Festool source as the reasoning for my actions, I don't think Festool would be obligated to cover a warranty repair.

WarnerConstCo.

Member

- Joined

- Apr 14, 2008

- Messages

- 4,205

It's hard to shift gears in a truck if you don't use the clutch when you are supposed to.

Similar threads

- Replies

- 6

- Views

- 623

- Replies

- 22

- Views

- 441

- Replies

- 21

- Views

- 2K