sawdust-samurai

Member

- Joined

- Jun 23, 2024

- Messages

- 88

So this afternoon I cut some 3/4" MDF down for a workbench top that I'm making. I used my Makita track saw and two 55" guide rails. I also used my TSO guide square.

First I cut 1/4" off one long edge as a reference edge. I then measured 47" from my reference edge and made a parallel cut down the other long edge of the MDF. Next, I took my TSO guide square (squared against my first reference cut) and cross cut another 1/4" reference cut, this time along the short edge of the MDF. I then proceeded to measure 67" from this short side reference cut and made a mark. I then moved my guide square and guide and lined it up on this mark, making sure it was squared to the original long edge reference edge and made my final cross cut.

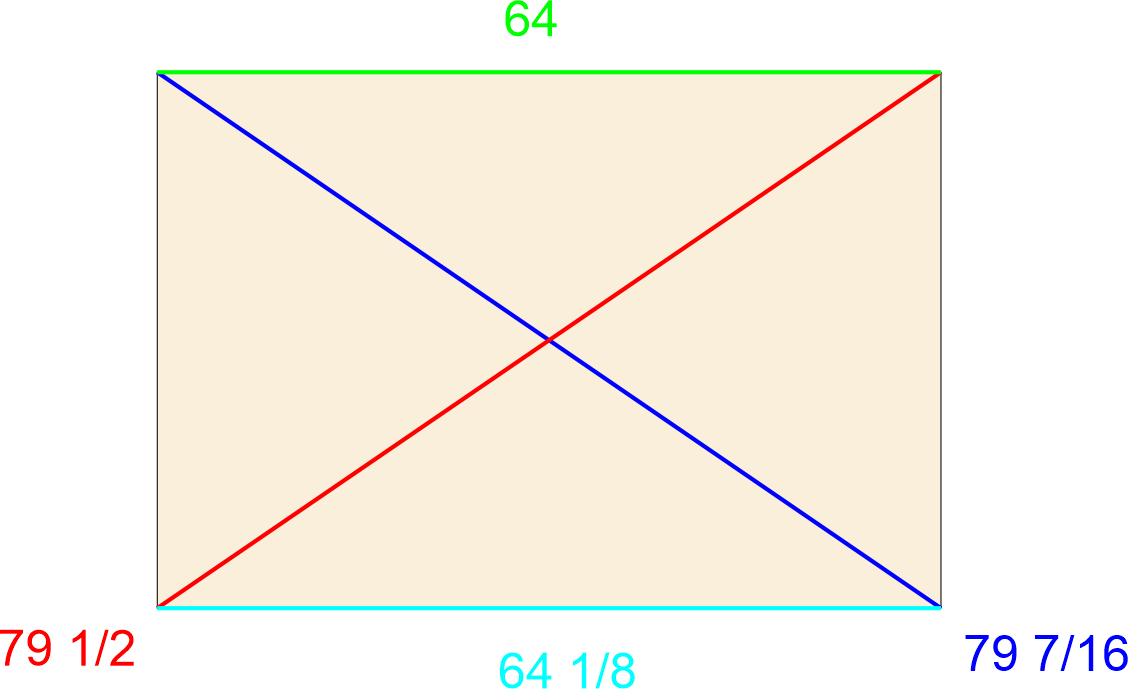

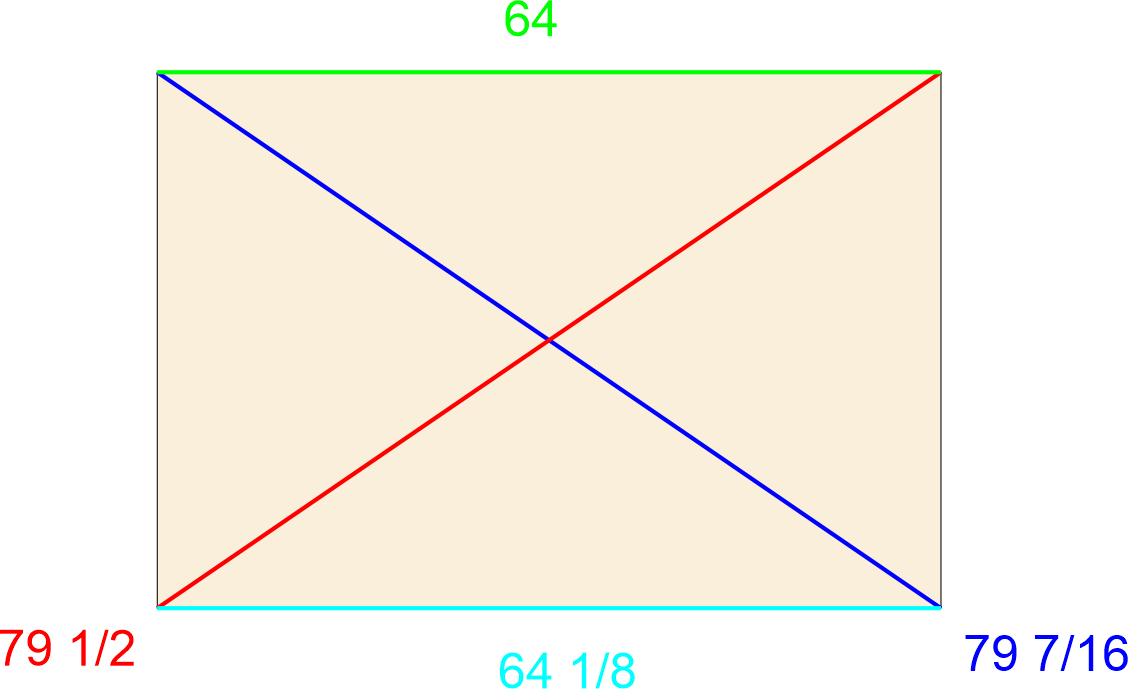

When I measure using the corner to corner method, one is a hair over 79 7/16" and the other is just a hair under 79 1/2".

Not perfectly square, but somewhere between say 1/32 and 1/16 off..

When I measure the lengths of the two short sides, they are off by 1/16. I can live with that for this bench top. What I don't understand is when I measure the long sides, one of this is 1/8 longer than the other. What throws me off even more, when I put either my Woodpeckers 851 square of my large 48" drywall T square against all of the corners, they all show as square.

How is it possible that my diagonal is less than a 1/16 off and all four corners checkout as square, but that one long side measures 1/8 longer?

First I cut 1/4" off one long edge as a reference edge. I then measured 47" from my reference edge and made a parallel cut down the other long edge of the MDF. Next, I took my TSO guide square (squared against my first reference cut) and cross cut another 1/4" reference cut, this time along the short edge of the MDF. I then proceeded to measure 67" from this short side reference cut and made a mark. I then moved my guide square and guide and lined it up on this mark, making sure it was squared to the original long edge reference edge and made my final cross cut.

When I measure using the corner to corner method, one is a hair over 79 7/16" and the other is just a hair under 79 1/2".

Not perfectly square, but somewhere between say 1/32 and 1/16 off..

When I measure the lengths of the two short sides, they are off by 1/16. I can live with that for this bench top. What I don't understand is when I measure the long sides, one of this is 1/8 longer than the other. What throws me off even more, when I put either my Woodpeckers 851 square of my large 48" drywall T square against all of the corners, they all show as square.

How is it possible that my diagonal is less than a 1/16 off and all four corners checkout as square, but that one long side measures 1/8 longer?