Well, I got fed up with switching over the power and the hose on my Festool vacuum when I have two power tools on the go, so I came up with the Switcher.

It is not finished yet, I just need to paint it and connect the electrics.

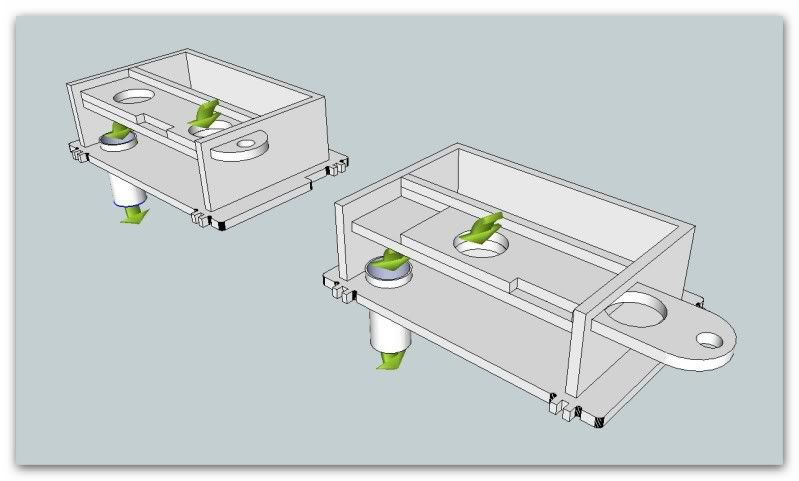

The concept was to plug in two tools to the power output on the vacuum and to be able to swap the extract hoses quickly.

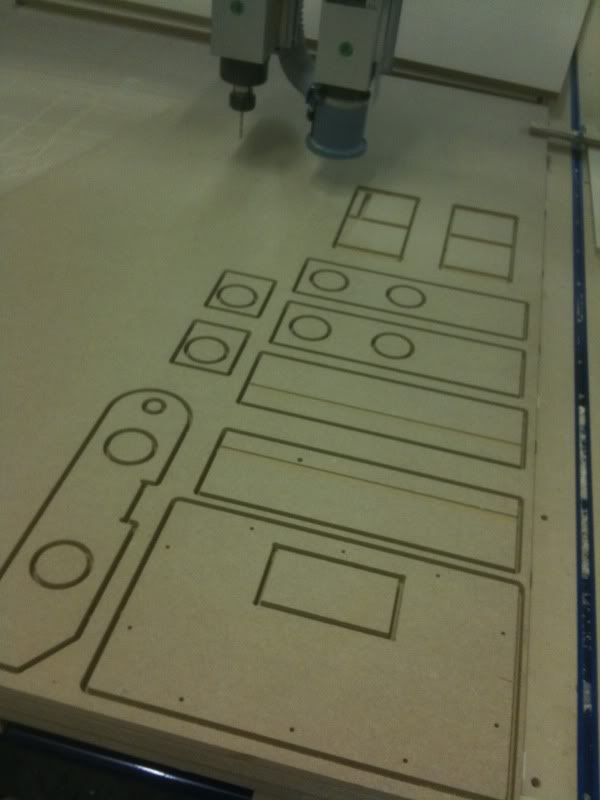

I cut the parts out on the CNC, sorry about the cr*ppy pictures

The base clips into the case clips

The inside has a divider for the electrics on the right, on the left is a short length of 2" waste pipe that pushes into the vacuum outlet and then enters the

bottom of the switcher, above that is a slider that has a couple of holes, one or the other is blanked off when you push or pull it.

Well it works a treat, I will post some more pictures when I have painted and wired it up

It is not finished yet, I just need to paint it and connect the electrics.

The concept was to plug in two tools to the power output on the vacuum and to be able to swap the extract hoses quickly.

I cut the parts out on the CNC, sorry about the cr*ppy pictures

The base clips into the case clips

The inside has a divider for the electrics on the right, on the left is a short length of 2" waste pipe that pushes into the vacuum outlet and then enters the

bottom of the switcher, above that is a slider that has a couple of holes, one or the other is blanked off when you push or pull it.

Well it works a treat, I will post some more pictures when I have painted and wired it up