4nthony

Member

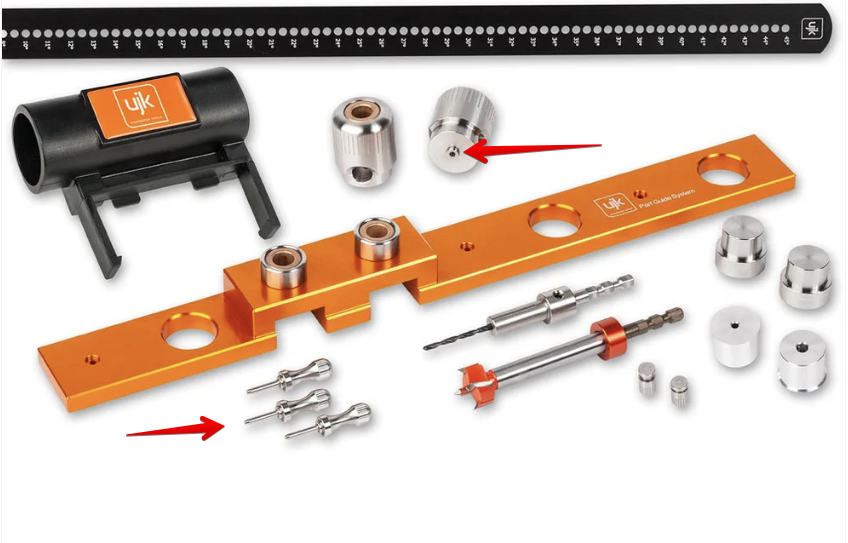

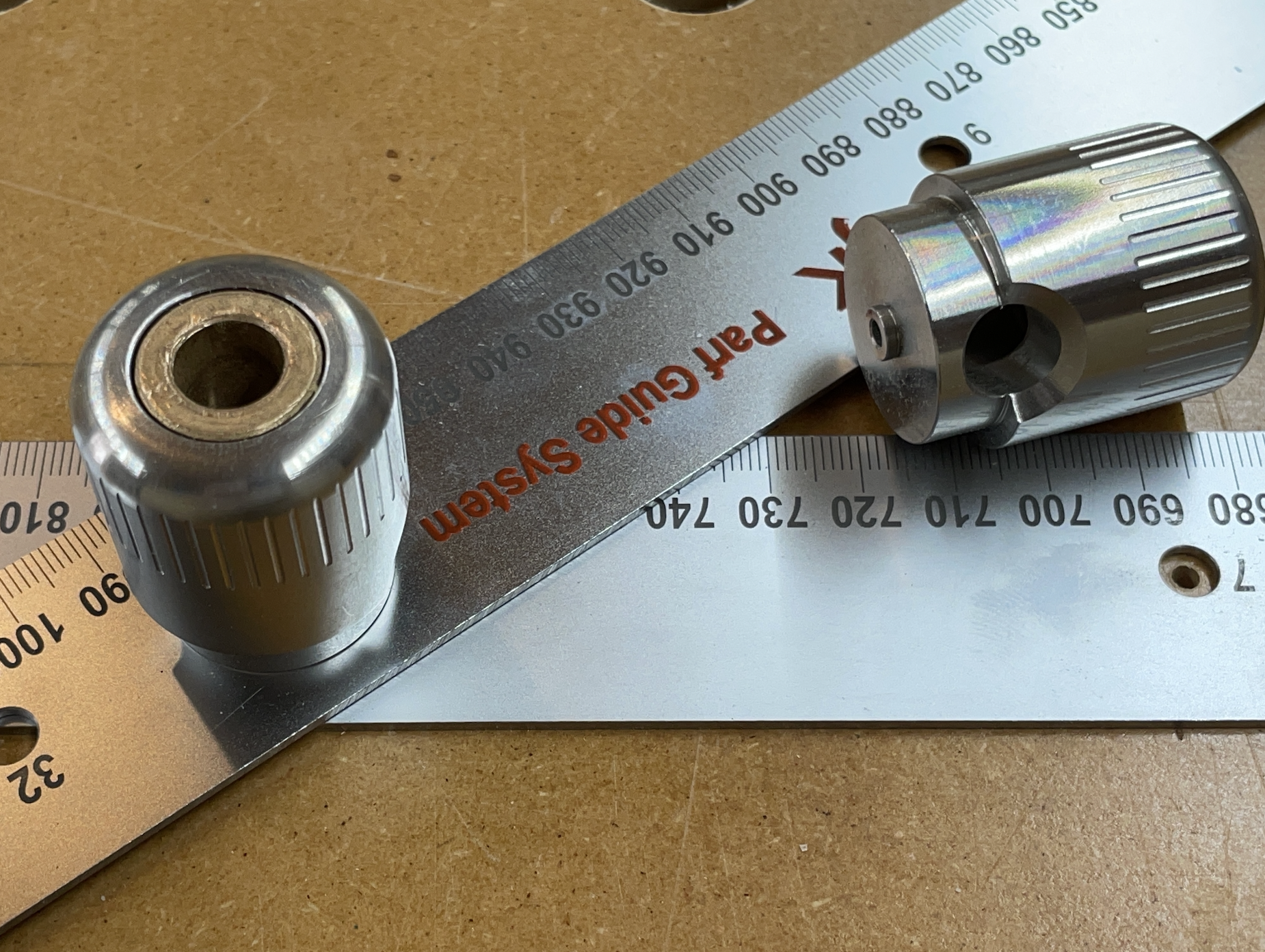

I received a UJK Parf Guide MK II from Axminster Tools yesterday and one of the first things I noticed is some slop in the drill guides.

For those of you with the MK II system, how snug do your drill guides fit into your rulers? Are they looser than your pins? My pins are right on the cusp of 5.95/5.96 and the drill guides are at 5.94.

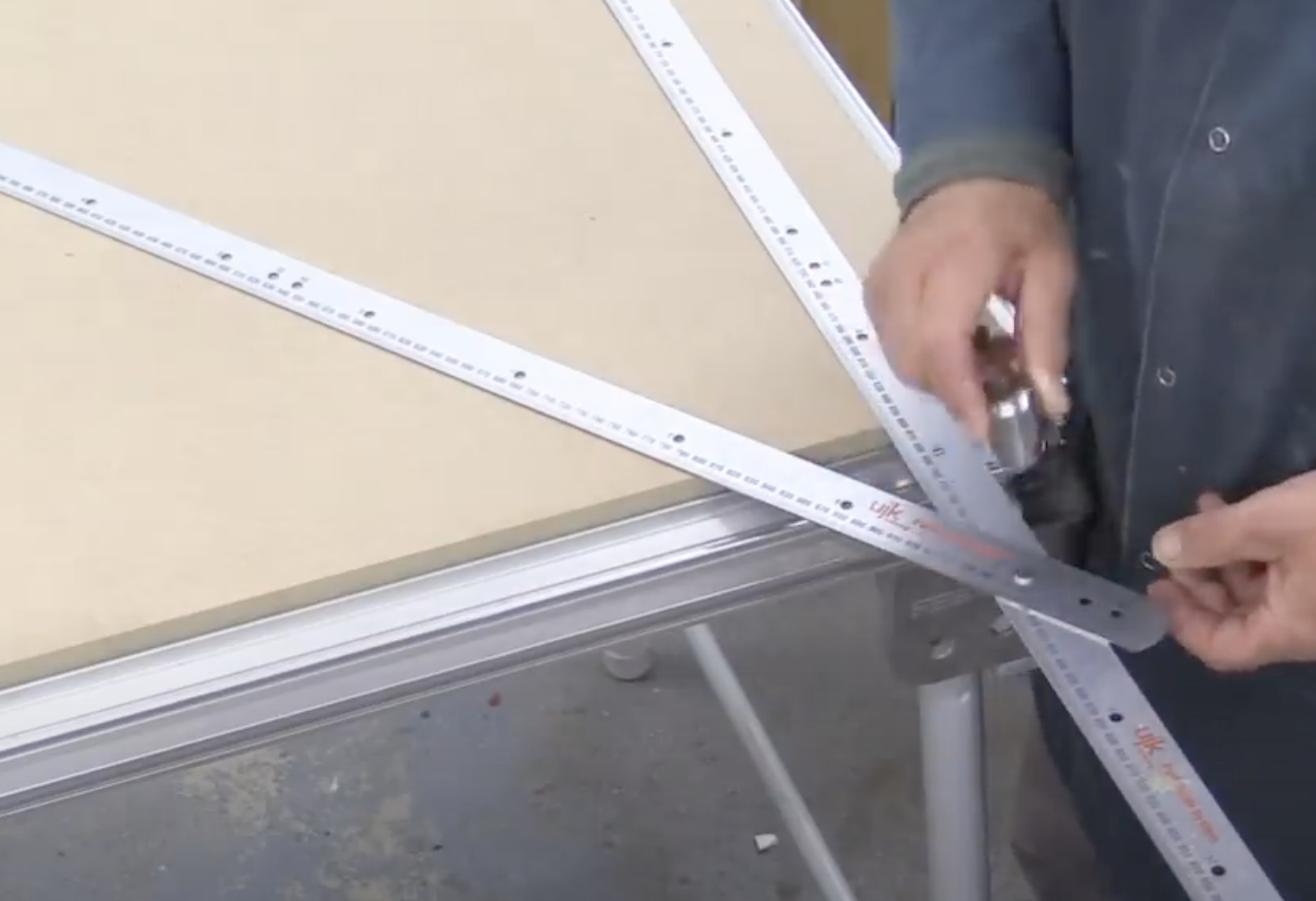

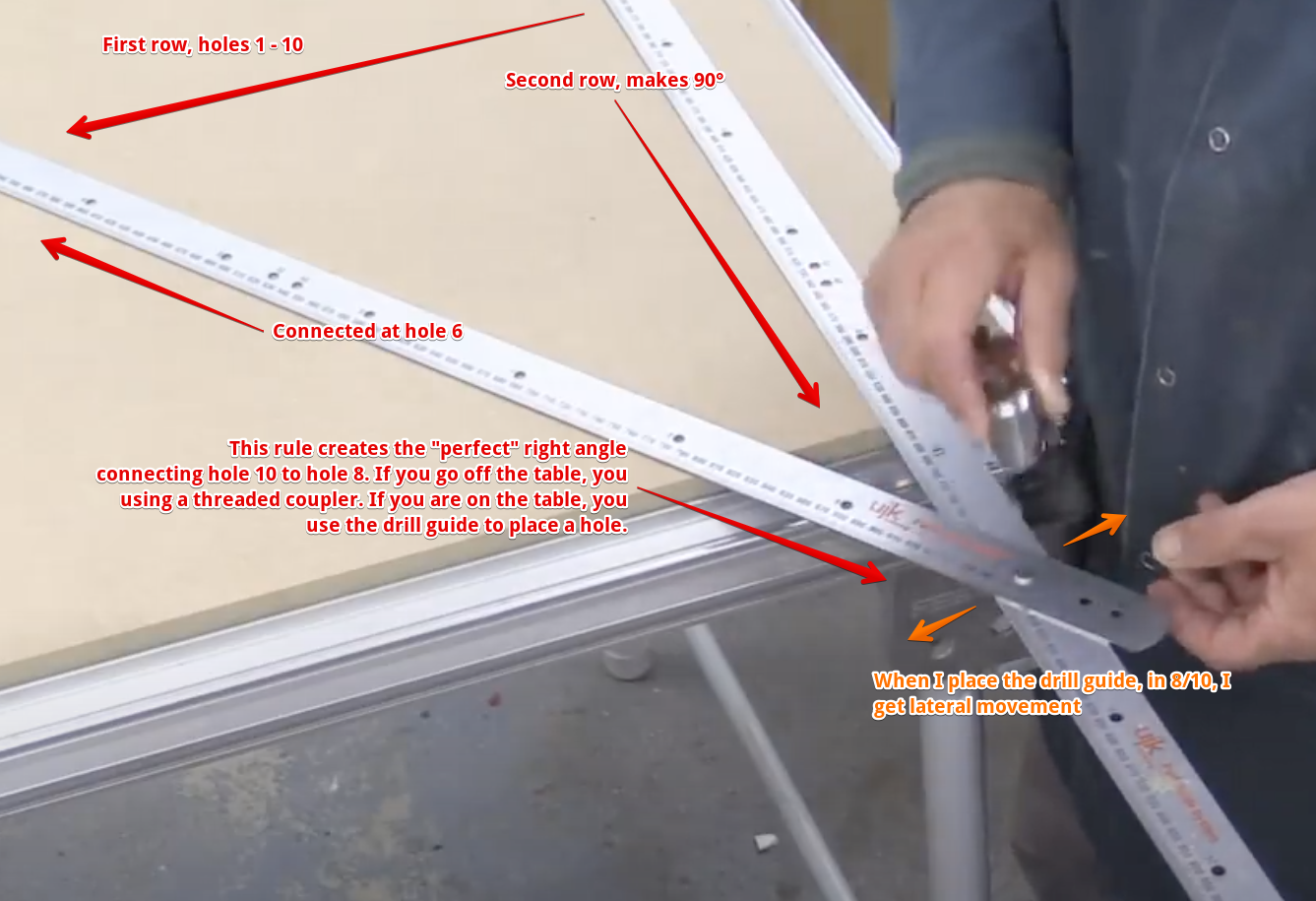

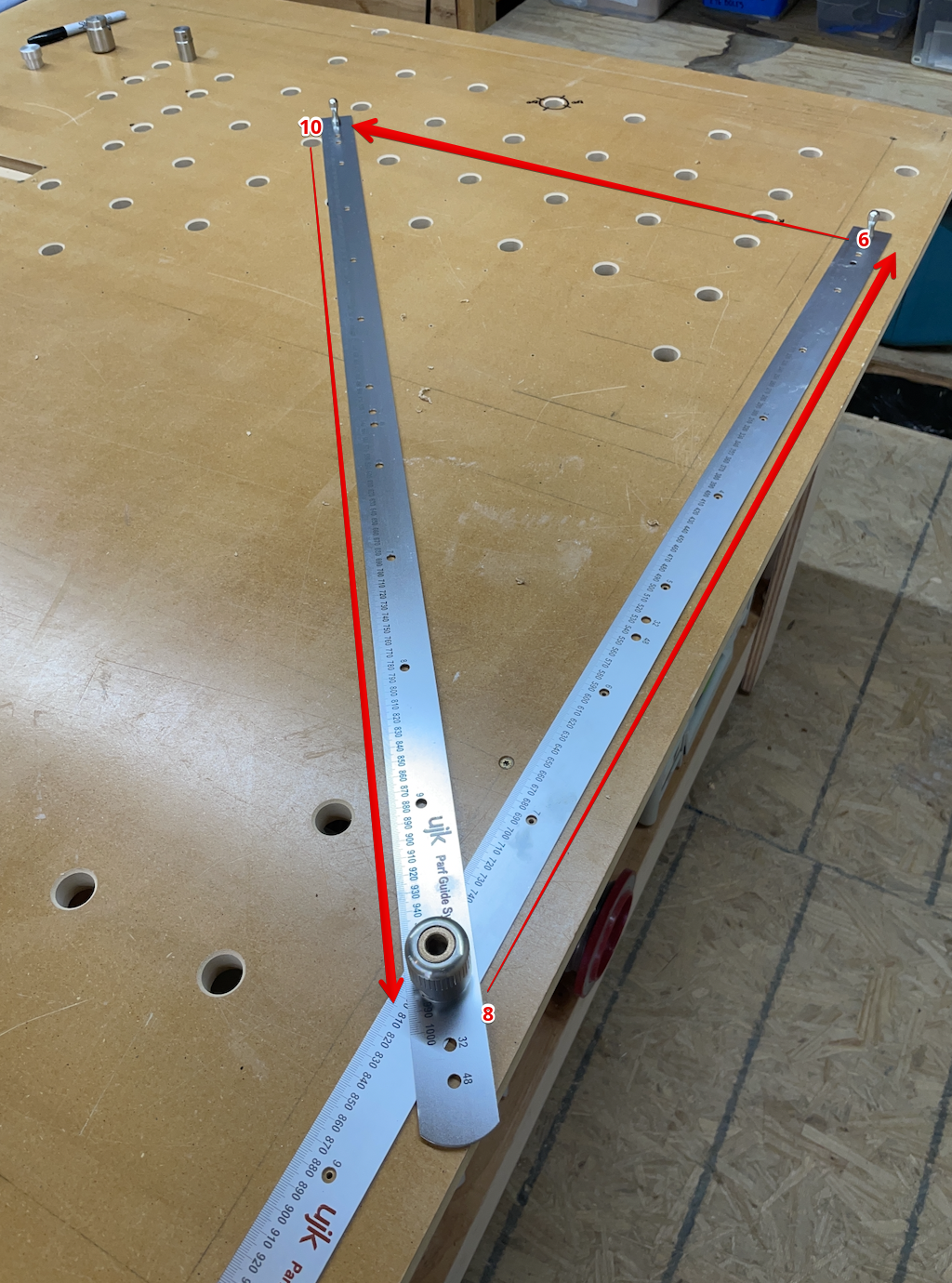

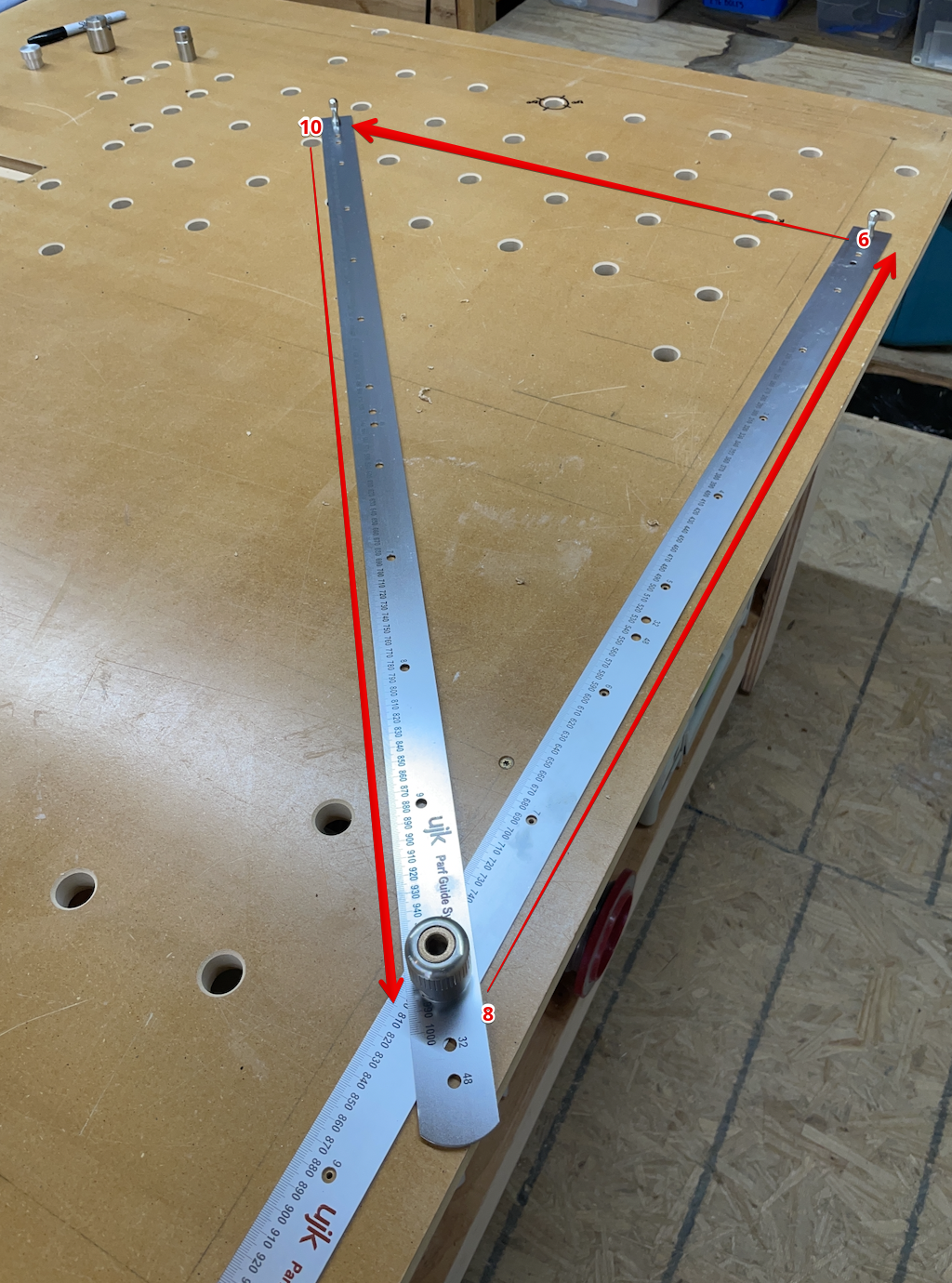

In this clip, the double length drill guide is seated into both rulers at the top of the triangle (see bottom photo):

I have the UJK Track Saw Set and my goal is for the outfeed table to have roughly 8 dog holes (2 for guide rails, 6 for a fence) on a right angle to make crosscuts on large material. I'm not planning on having a full grid.

Testing with a straight edge resulted in:

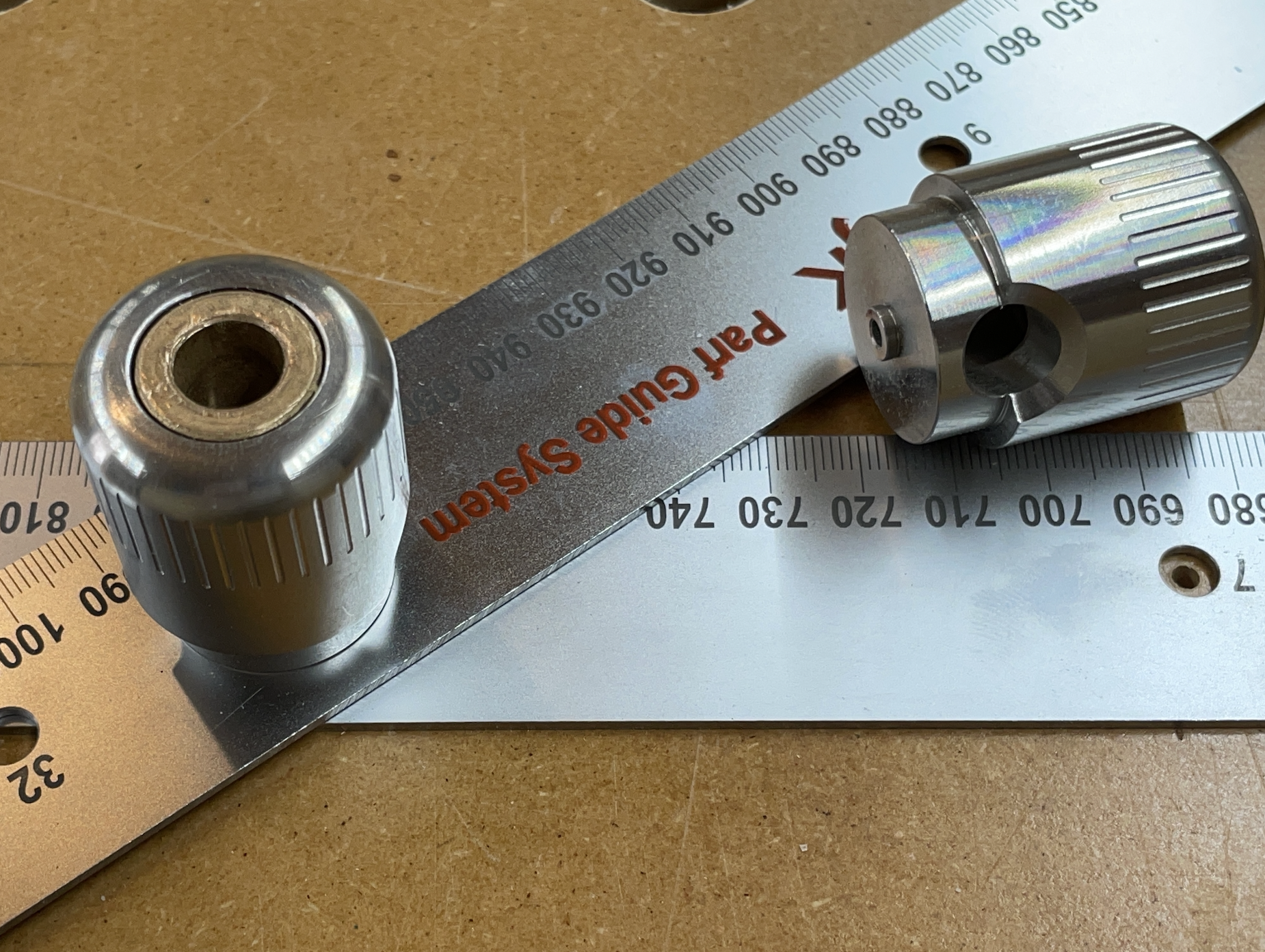

This is where the play in the first video is happening using the deeper drill guide. I've seen videos where this corner get clamped but I'm wondering if there should be any play? The pins themselves are nice and snug but the drill guides, not so much.

If this play is common, then most likely my technique resulted in the failed straight edge test. But the amount of play in the drill guide kinda -- read, unscientifically -- feels like the same amount in the straight edge.

I had some preexisting dog holes on the table that were done with an Origin (and which are also slightly out of square) so I used the Parf Guide between the existing holes. For the most part, the rulers all lined up and the pins fit without any issue.

The only real problem seems to be the play in the drill guides when inserted into the rulers.

The "Revision guides" I received to pair with the protractor also introduce quite a bit of slop but I'll save that part of it for later.

Does my hardware seem sloppy to you guys? I have not made any cuts yet so this may all be moot once the saw hits the wood -- it is woodworking after all and not rocket building -- but my OCD is OCD'ing and I keep hearing Peter Parfitt in the back of my head saying, "absolutely perfect"

For those of you with the MK II system, how snug do your drill guides fit into your rulers? Are they looser than your pins? My pins are right on the cusp of 5.95/5.96 and the drill guides are at 5.94.

In this clip, the double length drill guide is seated into both rulers at the top of the triangle (see bottom photo):

I have the UJK Track Saw Set and my goal is for the outfeed table to have roughly 8 dog holes (2 for guide rails, 6 for a fence) on a right angle to make crosscuts on large material. I'm not planning on having a full grid.

Testing with a straight edge resulted in:

This is where the play in the first video is happening using the deeper drill guide. I've seen videos where this corner get clamped but I'm wondering if there should be any play? The pins themselves are nice and snug but the drill guides, not so much.

If this play is common, then most likely my technique resulted in the failed straight edge test. But the amount of play in the drill guide kinda -- read, unscientifically -- feels like the same amount in the straight edge.

I had some preexisting dog holes on the table that were done with an Origin (and which are also slightly out of square) so I used the Parf Guide between the existing holes. For the most part, the rulers all lined up and the pins fit without any issue.

The only real problem seems to be the play in the drill guides when inserted into the rulers.

The "Revision guides" I received to pair with the protractor also introduce quite a bit of slop but I'll save that part of it for later.

Does my hardware seem sloppy to you guys? I have not made any cuts yet so this may all be moot once the saw hits the wood -- it is woodworking after all and not rocket building -- but my OCD is OCD'ing and I keep hearing Peter Parfitt in the back of my head saying, "absolutely perfect"