You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do you use for sharpening of hand tools?

- Thread starter RC

- Start date

Reiska said:Now that would be something [big grin]

Maybe throw in a hand held auto-leveling laser guided plane that will level arbitraty sized and shaped objects to selectable spec without human intervention - just fire and forget like modern robotic hoovers [wink]

Ah, I think Festool's Engineering Department is looking for you Ray [wink]

Ah, well to wrap up this thread I finally pushed the button and ordered a Worksharp 3000 kit with the knife sharpener, the wide blade platform accessory some extra glasses and the leather buffing wheel from Rutlands (they had it on discount and an additional -15% off for the summer SUMMER15 code). Now waiting for UPS to do their thing. [big grin]

In the meantime I've been using the scary sharp method to somewhat good results, but can't be bothered to put in all the elbow grease it requires to flatten chisels and plane bottoms and got the Veritas MkII guide with the skew blade attachment.

In the meantime I've been using the scary sharp method to somewhat good results, but can't be bothered to put in all the elbow grease it requires to flatten chisels and plane bottoms and got the Veritas MkII guide with the skew blade attachment.

joiner1970

Member

- Joined

- Jun 13, 2007

- Messages

- 3,163

Reiska said:Ah, well to wrap up this thread I finally pushed the button and ordered a Worksharp 3000 kit with the knife sharpener, the wide blade platform accessory some extra glasses and the leather buffing wheel from Rutlands (they had it on discount and an additional -15% off for the summer SUMMER15 code). Now waiting for UPS to do their thing. [big grin]

In the meantime I've been using the scary sharp method to somewhat good results, but can't be bothered to put in all the elbow grease it requires to flatten chisels and plane bottoms and got the Veritas MkII guide with the skew blade attachment.

They are good I got the same package from rutlands a couple of years ago. Just watch the smoldering swarf that flys out the back it could start a fire if you're not careful.

Have fun

Reiska said:Most other threads here seem to be comparing the Tormek T-7 and Worksharp to each other, but

- Is the T3 any good? Do you need to have machine power to keep stuff sharp?

- Is using stones and the Veritas guide usable and easy for keeping chisels & plane blades sharp? Which grits would you suggest? Oil vs. water stones? Other guide systems?

Since I'm a hobbyist I don't need to sharpen blades by the boatload nor an extra 5min per blade bother me at all, but if setting up is tedious (machines?) or its hard to get the sharpening done right (stones & manual guide) it will be a no-go.

Currently I have absolutely nothing to sharpen anything but kitchen knives (diamond sharpener for them) so anything is probably a win [blink]

Axminster is having a sale on Tormek T-3's and for some time I've been eyeing the Veritas Mk.II Honing system & stones to go with it.

i have a t7, but the t3 will work fine for you.

you can't run it nonstop, but why would you want to?

the difference in radius on the wheel will not make any

difference to what you are sharpening.

the only real difference is that tormek doesn't make

a japanese stone for the smaller machine, i don't believe.

eventually i'll end up with the japanese stone, and not

even bother with the leather strop wheel.

attachments are the same.

i have a number of attachments, but truth be told, if all

you are sharpening is kitchen knives, the flat adjustable

rest will allow you to quickly sharpen all your knives quite

well.

I use the norton waterstone box. Here is a link to my review on lumberjocks http://lumberjocks.com/reviews/1520.

I also have a diamond plate in coarse and fine and a small credit card diamond stone (awesome for keeping planer knives sharp) .

I must confess that I have looked at getting a Worksharp and Tormek myself, leaning towards the worksharp 3000 because I don`t like a hollow grind ( I know its a terrible blasphemy !!) since using Japanese chisels which are never hollow ground due tho the thin hard laminated layer.

Ollie

I also have a diamond plate in coarse and fine and a small credit card diamond stone (awesome for keeping planer knives sharp) .

I must confess that I have looked at getting a Worksharp and Tormek myself, leaning towards the worksharp 3000 because I don`t like a hollow grind ( I know its a terrible blasphemy !!) since using Japanese chisels which are never hollow ground due tho the thin hard laminated layer.

Ollie

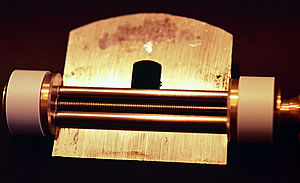

I use Japanese water stones, I have a 700 grit, 1200 grit and a 4000 grit and they with the aid of the new Veritas Mark 11 is all I need. I had three other sharpening aids but, the new Veritas is well engineered and overcomes all of the deficiencies of the others I have owned.

I must admit that with small tools and short plane blades I just use my fingers to hold the edge to the stone. If done carefully you can get a really fine edge but beware when you start to see a red tinge (that's your blood oozing out when you polish off too much skin).

Jack

I must admit that with small tools and short plane blades I just use my fingers to hold the edge to the stone. If done carefully you can get a really fine edge but beware when you start to see a red tinge (that's your blood oozing out when you polish off too much skin).

Jack

wrightwoodwork

Member

- Joined

- Jul 1, 2013

- Messages

- 410

There isn't a 100% best way to sharpen tools I have an old type tormek t3 woriks great and does the job very easily great for setting a bevel on your tools very easily. The pros are that anyone can sharpen on them after less than 5minutes being shown. The negative is it is too bulky to use else where if you work on job sites or away from the workshop. I now use a combination 1000 & 6000 water stone separates are better but for handiness a combination works fine and is convenient for myself. The advantage is using stones you can get a far sharper tool and is more convenient to use anywhere. The disadvantages is that it takes time to learn and isnt as easy as the tormek, but if learned to do the sharpness that can be achieved is worth the learning. There is no need for any fancy jigs. If you learn to do without you will sharpen more as it is second nature after a while when sharpening the only two things that matter is first the back is flat, hence why the stone needs to be flat and the bevel angle is at a constant doesn't matter if it is not a perfect 25 degrees. If less you will get sharper edge but the trade off it will be slight weaker. If you go above 25 you will get an edge more suited to chopping but not as suited to paring. 25 tends to be a good all round angle. The aim is to get the angels where it meets the flat to achieve 0. It does take practice and lots of it but isn't really that hard to do. The secret is to relax a little and not be too rigid. The tools are not going to sharpen any faster by pushing harder on them in fact all you will end up doing is digging into the stone. Once the back has been flattened it is time to do the angle. To do the bevel presuming there is no chips or the like is to rock the chisel back and forth till you feel the bevel sitting firmly on the stone. At this point raise the handle a couple of degrees, unless removing any chips in the blade and lock your wrists at that angle. Do approximately 5 or 6 strokes to check if the wire edge is being formed. Once the wire edge is formed it is just a case of a couple of strokes on the back to remove. Then the bevel another couple of strokes and finally finish with some strokes on the back once mastered it really is that hard to do. It's best to practice on chisels over 3/4 as not too narrow. Also when sharpening the like of a jack plane iron the blade should have a slight concave do when you are using no line are produced in what is being planed

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 18

- Views

- 7K

![honingGuide3.jpg]](http://www.richardkell.co.uk/images/honingGuide3.jpg])