You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who can identify this?

- Thread starter afish

- Start date

- Joined

- Sep 10, 2014

- Messages

- 239

I'm not sure but aren't confirmat screws blunt on the end? Also, the threads on confirmat may be coarser. Looks like a rabbit hole....where was that screw used?

Thanks found some at woodworkers express but they cost more than I can buy the smaller confirmats so I think I will try those first. I usually love the confirmat screws in just about everything except plywood recently. The 7/5mm confimats have started to separate the ply's in plywood even when predrilled. Im going to try the smaller ones and see if they are better in plywood.

Dongar

Member

Found these at Rockler clearance.https://www.rockler.com/hi-lo-screws-product-options

Packard

Member

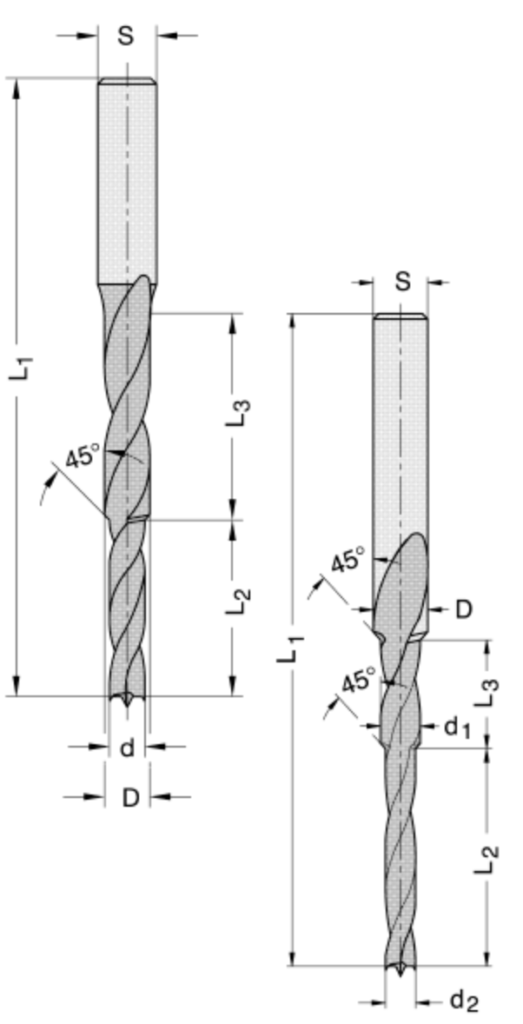

The picture looks like the confirmats that Amazon sells:

I buy my confirmats from AH Turf and Woodworker's Express. AH Turf will sell moderate quantities at a good price, but their website is ponderous to use. I just went there and searched for "confirmats" and was directed to "screws", and after 13 slow loading pages I gave up.

Woodworkers Express sells these at a very good price, but with a 2,000 screw minimum ($72.00). But their website is a pleasure to use. Both are reliable vendors.

Using AH Turf's website for Blum hinges is even more tedius. But good prices and good service.

A number of years ago I was researching fasteners and I found that the RTA (Ready to assemble) furniture trade association hired an outside consulting company to compare fastener strength. They were really interested in racking strength. Would the assembled furniture rock from side to side.

Also the kitchen cabinet trade association did the same. But since the cabinets get mounted to the wall, racking strenth was not high on their strenth requirements.

They compared:

Half-turn/quarter turn fasteners for the joints

dry wall screws

dadoes

confirmat screws

dowels

While dominoes would probably fare well, they are not widely used in the industry (large companies mostly).

Their findings were almost identical.

The test was to attach a shelf on one edge to a vertical panel and then add load until the joint failed. No glue was used.

The dado failed before any measurable load could be applied.

The 1/4 turn fasteners did a little better.

The drywall screws did better than the 1/4 turn.

The confirmats and the dowels were tied.

From a production point of view, the dowels were the clear winner. They were strong and inexpensive and there are automated machines available that will gang drill, gang install dowels & glue. None of the other systems were as fast or as inexpensive.

The confirmats combine the holding power of a screw with the racking strength of a dowel. I combine the two on face frame cabinets. The confirmats eliminate the need for many clamps. I through drill the dowels and glue. Side panels will hide the fasteners and dowel holes.

Confirmats also can be removed and re-installed with no loss of holding power. The drywall screws cannot.

In any case, the Confirmats are an excellent fastener choice. But expensive if you don't find the right source (Hint: Home Depot and Amazon.com are not the right sources.)

I buy my confirmats from AH Turf and Woodworker's Express. AH Turf will sell moderate quantities at a good price, but their website is ponderous to use. I just went there and searched for "confirmats" and was directed to "screws", and after 13 slow loading pages I gave up.

Woodworkers Express sells these at a very good price, but with a 2,000 screw minimum ($72.00). But their website is a pleasure to use. Both are reliable vendors.

Using AH Turf's website for Blum hinges is even more tedius. But good prices and good service.

A number of years ago I was researching fasteners and I found that the RTA (Ready to assemble) furniture trade association hired an outside consulting company to compare fastener strength. They were really interested in racking strength. Would the assembled furniture rock from side to side.

Also the kitchen cabinet trade association did the same. But since the cabinets get mounted to the wall, racking strenth was not high on their strenth requirements.

They compared:

Half-turn/quarter turn fasteners for the joints

dry wall screws

dadoes

confirmat screws

dowels

While dominoes would probably fare well, they are not widely used in the industry (large companies mostly).

Their findings were almost identical.

The test was to attach a shelf on one edge to a vertical panel and then add load until the joint failed. No glue was used.

The dado failed before any measurable load could be applied.

The 1/4 turn fasteners did a little better.

The drywall screws did better than the 1/4 turn.

The confirmats and the dowels were tied.

From a production point of view, the dowels were the clear winner. They were strong and inexpensive and there are automated machines available that will gang drill, gang install dowels & glue. None of the other systems were as fast or as inexpensive.

The confirmats combine the holding power of a screw with the racking strength of a dowel. I combine the two on face frame cabinets. The confirmats eliminate the need for many clamps. I through drill the dowels and glue. Side panels will hide the fasteners and dowel holes.

Confirmats also can be removed and re-installed with no loss of holding power. The drywall screws cannot.

In any case, the Confirmats are an excellent fastener choice. But expensive if you don't find the right source (Hint: Home Depot and Amazon.com are not the right sources.)

The screw I pictured is more like a drywall screw. But had that funky head and hi-lo threads even though they are hard to see. I really liked how they performed but only had a handful. I did find some but as I mentioned they were more than I can get the confirmats for, so Im going to try the smaller confirmats first.

Im a huge fan of confirmats. Unfortunately they can split or bulge plywood. Plywood is the only substrate that I have found to give me an issue from time to time with confirmats. Otherwise these things just rock. I use them in combination with 5mm dowels since the large confirmats use a 5mm pilot hole with a 7mm shoulder it works perfect with the DDF40 horizontal boring station I made. I use mostly dowels and just swap a couple dowels out for confirmats so I dont need to clamp anything. The only issue is I can run the risk of a bulge when using plywood It doesnt happen very often but it sucks when it does since its the last step and at that point everything is edgebanded and almost finished. They make a smaller diameter confirmat with a 5mm shoulder so Im thinking these will still work good. I will just use all dowels and add a couple confirmats after the fact. I have looked at a bunch of different RTA fasteners and the good ol' fashioned wood dowel and confirmat win every time for speed, simplicity, and cost. The only other one Im interested in trying is the Ovvo but at this point its like they say if it aint broke.

Thanks for that informative post. Happy to see my testing matched their testing

Im a huge fan of confirmats. Unfortunately they can split or bulge plywood. Plywood is the only substrate that I have found to give me an issue from time to time with confirmats. Otherwise these things just rock. I use them in combination with 5mm dowels since the large confirmats use a 5mm pilot hole with a 7mm shoulder it works perfect with the DDF40 horizontal boring station I made. I use mostly dowels and just swap a couple dowels out for confirmats so I dont need to clamp anything. The only issue is I can run the risk of a bulge when using plywood It doesnt happen very often but it sucks when it does since its the last step and at that point everything is edgebanded and almost finished. They make a smaller diameter confirmat with a 5mm shoulder so Im thinking these will still work good. I will just use all dowels and add a couple confirmats after the fact. I have looked at a bunch of different RTA fasteners and the good ol' fashioned wood dowel and confirmat win every time for speed, simplicity, and cost. The only other one Im interested in trying is the Ovvo but at this point its like they say if it aint broke.

Thanks for that informative post. Happy to see my testing matched their testing

Packard

Member

afish said:I'm a huge fan of confirmats. Unfortunately, they can split or bulge plywood.

Are you using the special stepped drill bit that they recommend. I have not had splitting or bulging issues with plywood, particle board or MDF.

[removed link as it is highly suspect.]

Amazon has the stepped bits too. The one-piece bits are about $60.00, but the two piece bits are less than half that.

Some further research shows that GN Classi is a scam. Do not buy from them.

https://www.scam-detector.com/validator/gnclassi-com-review/

Is www.gnclassi.com legit? Nope. It has the lowest trust rating on our chart. Let's take a look at it and its General Merchandise industry. We put to work 53 powerful factors to expose high-risk activity and see if www.gnclassi.com is a scam. Below you could also find helpful comments.

Yes I do but since the 5mm pilot hole is already there Im really just opening up for the 7mm shoulder. Most materials I dont need the bit but with plywood I chase it out just incase, I dont remember having any issues with pre covid plywood but the post covid plywood has given me trouble. I got a batch from a different supplier since it was so hard to get and that stuff was really bad. My normal supplier got more and I havent had any issues with that batch but next time I place an order Im going to get 1k of the smaller ones and try them out just to hedge my bets. This issue so far has only been in what we call "cabinet liner" which is plywood with a V grade laminate on one or both sides. I havent tried any prefinished ply yet.

Similar threads

- Replies

- 2

- Views

- 323

- Replies

- 32

- Views

- 2K

- Replies

- 8

- Views

- 645

- Replies

- 0

- Views

- 49K

- Replies

- 19

- Views

- 603