Packard

Member

I avoid measurements whenever possible.

If I want to create a hexagon, I know each cut has to be 60 degrees.

So I set my saw at the theoretical 60 degrees and make cuts on two opposite ends of a board. Then I slice that board to 2” width pieces. I then tape the mitered ends together into one long strip and fold it to a hexagon. I then make adjustments to the angle of the cut ends until it makes a perfect hexagon. I rarely have to make more than two samples.

I don’t actually recall assembling a hexagon. But I have used this technique for rectangles and squares when required.

I do have a highly precise 45 degree only sliding table saw. It can handle a maximum of about 4” width.

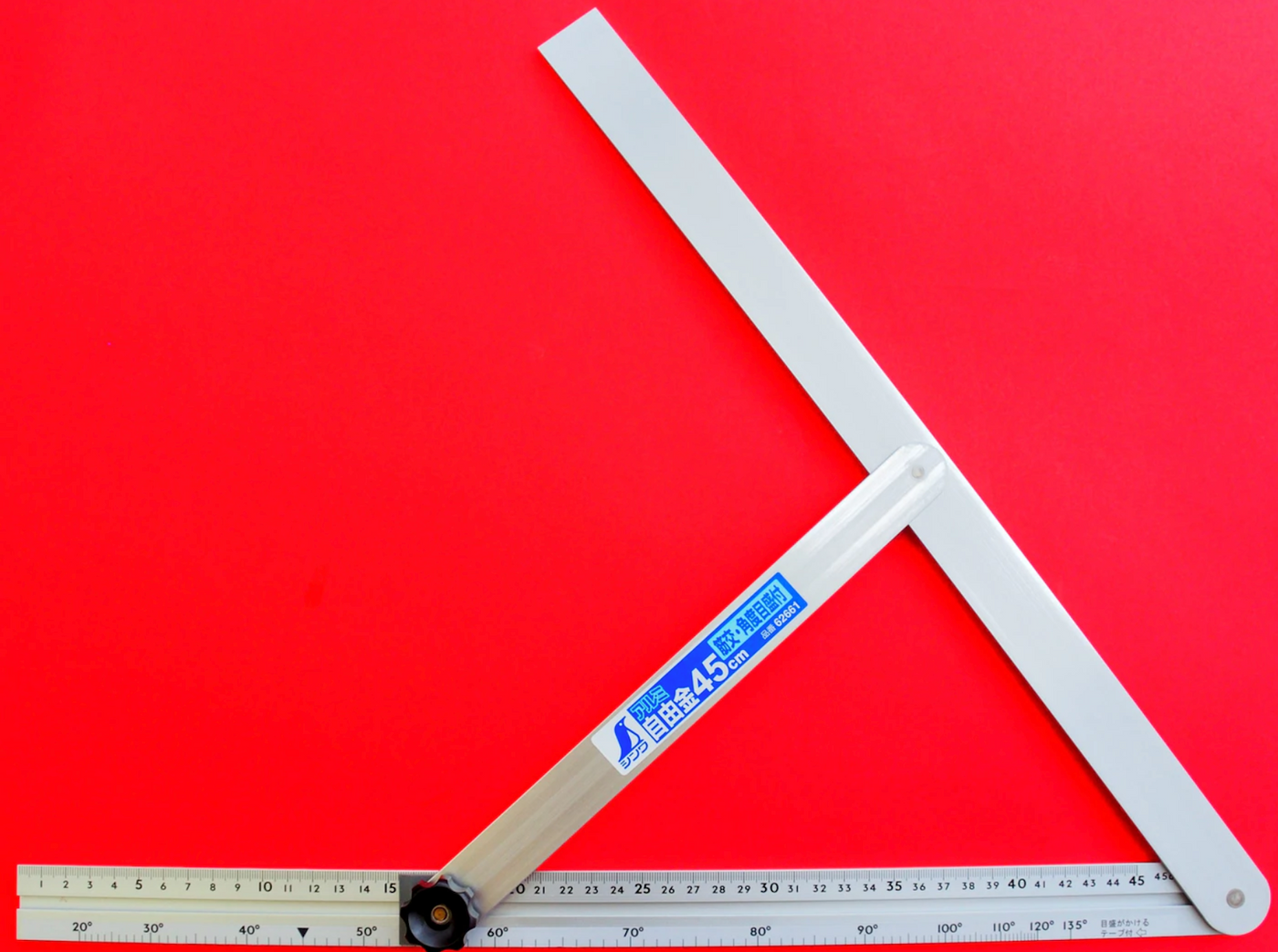

I did make an end table with miters along the 16” height a while back. But not since. I won’t be buying any precision angle measuring devices.

If I want to create a hexagon, I know each cut has to be 60 degrees.

So I set my saw at the theoretical 60 degrees and make cuts on two opposite ends of a board. Then I slice that board to 2” width pieces. I then tape the mitered ends together into one long strip and fold it to a hexagon. I then make adjustments to the angle of the cut ends until it makes a perfect hexagon. I rarely have to make more than two samples.

I don’t actually recall assembling a hexagon. But I have used this technique for rectangles and squares when required.

I do have a highly precise 45 degree only sliding table saw. It can handle a maximum of about 4” width.

I did make an end table with miters along the 16” height a while back. But not since. I won’t be buying any precision angle measuring devices.