Packard

Member

Not as detailed as I would like, but no wasted video footage.

Packard said:For me, repeatability is more important than accuracy.

You were correct. The spam bot edited the post to add a URL.squall_line said:The original post was probably a legitimate review from a long-time lurker who decided not to continue to participate on the boards. The necro-bump (resurrection of the thread from the grave) was likely a spam bot that was/is supposed to return at a later date to edit their post with a spam link.

smorgasbord said:BTW, the tablesaw DRO is specced at +/-0.002" per foot. I periodically check my rip results with a digital caliper.

Mini Me said:...make INCRA fences as one example obsolete and my INRA fences I have are being sold as soon as I have the time to set up DRO's on my machines. Wixey are also very expensive and hard to use compared to the new DRO's now available and I sold mine, it is a pity Wixey have not moved on as they made the original digital break through for the hobbyist.

smorgasbord said:I still have Incra racks on my tablesaw sled fence and for my miter gauge. What are you going to use there?

Mini Me said:The cheap DRO's which are all very accurate and now available for under $100 make setting fences to an accurate dimension are a game changer and make INCRA fences as one example obsolete and my INRA fences I have are being sold as soon as I have the time to set up DRO's on my machines. Wixey are also very expensive and hard to use compared to the new DRO's now available and I sold mine, it is a pity Wixey have not moved on as they made the original digital break through for the hobbyist.

simnick said:Mini Me said:The cheap DRO's which are all very accurate and now available for under $100 make setting fences to an accurate dimension are a game changer and make INCRA fences as one example obsolete and my INRA fences I have are being sold as soon as I have the time to set up DRO's on my machines. Wixey are also very expensive and hard to use compared to the new DRO's now available and I sold mine, it is a pity Wixey have not moved on as they made the original digital break through for the hobbyist.

Can you give me a pointer to some of the better DROs? I have the Wixley, but it got uninstalled while everything is in storage for a shop move, and rather than reinstall it, maybe I can put something better on.

smorgasbord said:I have the Shinwa 60cm bevel on its way to me now. I will probably also order a Wixey digital protractor since its spec is +/-0.10º versus everyone else's +/-0.2º. And then I'll compare the two and also against my 90º and 45º "squares," which are some pretty high DIN spec.

One thing I'm interested in is seeing if I can adopt the triangle to determine angle aspect of the Shinwa to a shop-built (CNC) mechanism to use on my table saw sled for setting accurate angles. The large protractor of the Rockler and Sullivan sleds might be better, but maybe not. It'll be fun to experiment.

Packard said:Let us know what you think of the Shinwa triangle. I am debating whether to get one myself. I have this Shinwa marking gage and I find myself using it far more often than my Starrett combination square. They make an aluminum version too. The clear (smoke) version lets you see markings under the square. I think I paid $6.00 for it a few years ago.

Michael Kellough said:The refresh rate is also important on digital protractors. Most of them let you move a shocking amount (relative to how much move the blade on a table saw when making a fine adjustment) before the display changes. And very few of them specify the refresh rate.

smorgasbord said:So, here are some preliminary results of the Shinwa #62662 60cm triangular bevel against the Wixey WR418 18" Digital Protractor. Note these are just comparing them to each other, not to known hard reference angles, since I don't have any of those with me at this point in time.

My process was to set the Shinwa, then measure the outside angle of that with the Wixey.

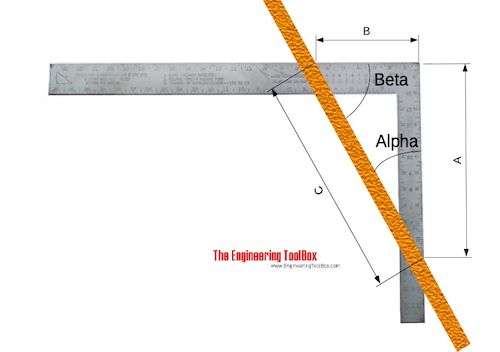

[attachimg=1]

For 45 and 75, they were both spot on in agreement:

[attachimg=2]

[attachimg=3]

Even for 22.5º, which requires splitting the distance with your eye, the results for me (twice) were spot on:

[attachimg=4]

At 90º I got an 89.9º readout on the Wixey one time, then 90º two other times. Note that there is some play in the Shinwa alignment guide until you lock it down. I think it is possible to push it one way or the other to get a slight angle change. But, you can see from the mm markings above that the scale (in this 60cm size) is quite large, reducing the effects of any inaccuracy.

As you move up the angle scale to higher numbers, I believe the Shinwa gets less accurate. Here's one shot at the 120º mark:

[attachimg=5]

[attachimg=6]

Maybe I'm wrong in assuming the Wixey is more accurate than the Shinwa at these angles, but when you look at the Shinwa scale, the degree markings get close the higher the number value. The distance between 119º and 120º on the Shinwa is just over a mm, while the distance between 59º and 60º is easily more than 5mm (closer to 6mm). Once you get below 30º, the spacing gets tighter, too. The sweet spot of the Shina is from about 30º to about 85º.

I have some DIN graded squares and 45º reference triangles at home, and I'll compare against those when I can.

In the meantime, I think I'm going to keep both the Wixey and Shinwa. The Shinwa is less useful because it is graduated only in full degrees (I have had to split to get 22.5º by eye), and you even have to remember that the graduations vary as you go up and down so you're not going to get 0.1º of setting accuracy off of full and middle degree increments. That said, I think I might build my own Shinwa style arm for my tablesaw cross-cut sled for angle cuts once I figure out the math to get in-between whole degree angles. With 5mm between degree marks, it should be pretty easy set 1/10º marks for the sweet spot of that geometry.

Then again, the Wixey is big enough that maybe I could mount it to the sled and just have a way to fix the arm as a back fence. The triangular nature of the Shinwa means that it holds its setting really well. They show people using it as a circular saw guide for cutting rafter angles and such, and I bet it does well at that.