BeerCanPyramids

Member

- Joined

- Mar 30, 2022

- Messages

- 3

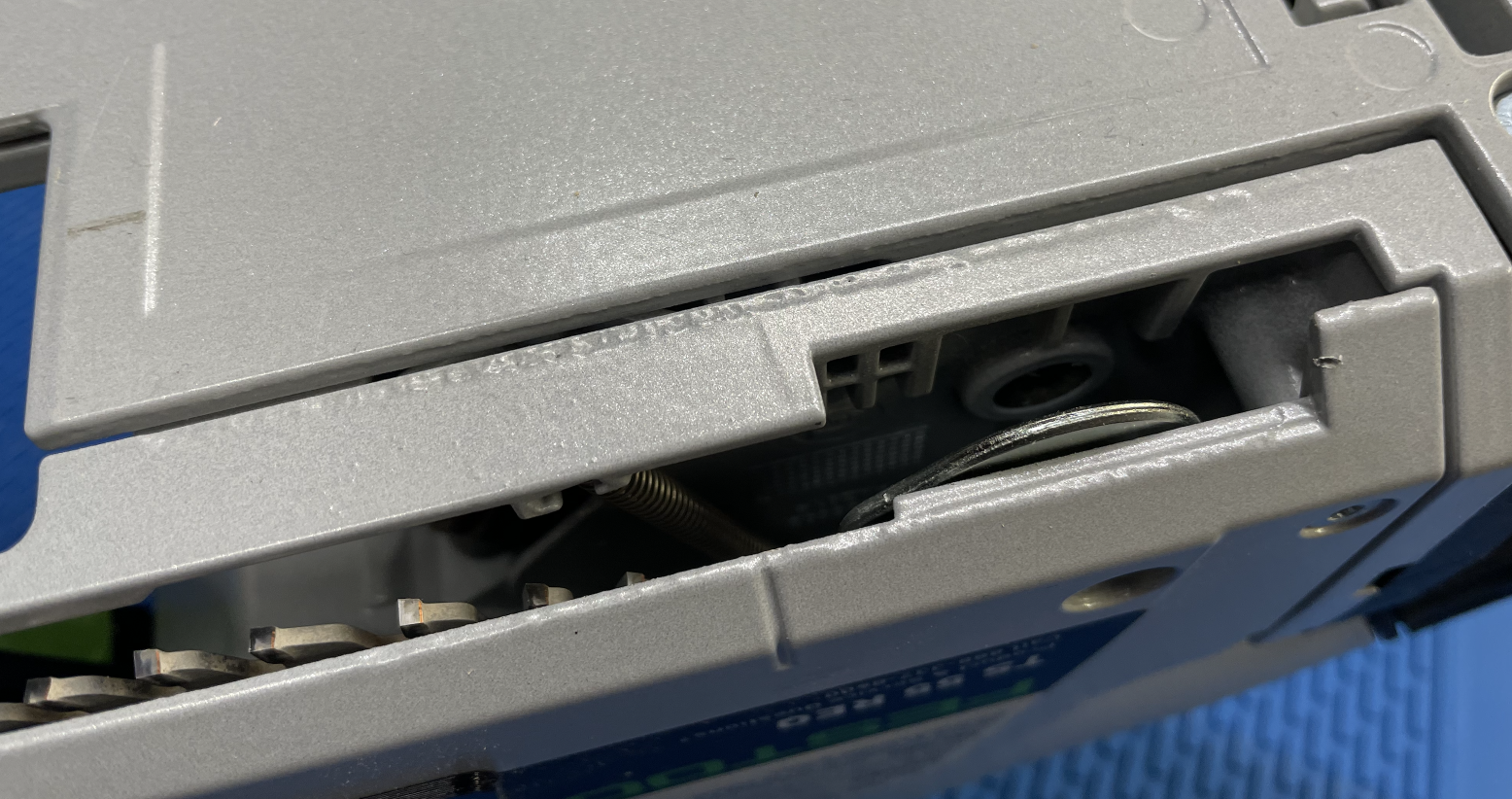

Just unboxed a TS 55 FEQ (purchased from BIS) and found some rough edges on the baseplate. Looks like poor casting, pitting, and/or powdercoat. It doesn't seem to effect proper guiderail operation; but I'm new to the TS 55 FEQ and haven't actually cut with it yet. Considering the $699 price tag, would you try and exchange it for a better one? Or are some rough edges just part of the deal? Hard to photograph but it feels like all edges should be straight & smooth out of the box.

View attachment 1 View attachment 2 View attachment 3 View attachment 4

View attachment 1 View attachment 2 View attachment 3 View attachment 4