Michael Kellough

Member

They were hanging on the wall at Woodcraft Michael...@Cheese, are these easy to find or did you have to special order the bits?

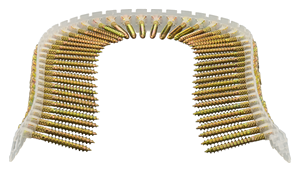

I have them in PZ2 as well; some other OSB screws -collated- with that head too.They were hanging on the wall at Woodcraft Michael......easier to purchase them now than a year from now. Also noticed that Festool offers a version for Torx 20 screws, I wonder what those are used for?

My brother has the 2500 Festool, I have the 4200rpm (previous) Bosch version. Both required insane pressure and then still it cammed out. Was Knauf diamondboard onto 120+ year old bone dry wood, insanely dense and slow-growth. About 25% needed to be driven deeper... which we ended up using the impact driver for.I haven't found that to be the case with decent quality bits. The cheapo ones I buy in bulk absolutely yes, I drive them to destruction, but I can't remember the last time I destroyed a good bit in a driver, and I easily go through probably 5k or so screws a year, mostly into very old Aussie hardwood studs. Snapped screws are the real issue there.

It definitely does help to "get in the groove" when using collated guns, to avoid camming out or ruining the nose end, just a little off angle or lack of tension can be costly.

Hmm, Festool seems to use regular 152mm bits while Bosch uses oddball 145mm bits.They were hanging on the wall at Woodcraft Michael......easier to purchase them now than a year from now. Also noticed that Festool offers a version for Torx 20 screws, I wonder what those are used for?

How did you arrive at the idea of 55mm bits working? Bit holder + bit is way longer than that for single-screw use. See; https://festoolownersgroup.com/threads/4500-drywall-screw-gun-discontinued-in-usa.75732/#post-732977Will other bits that are 55mm long work? Does anyone have any experience?

Great info Coen!How did you arrive at the idea of 55mm bits working? Bit holder + bit is way longer than that for single-screw use. See; https://festoolownersgroup.com/threads/4500-drywall-screw-gun-discontinued-in-usa.75732/#post-732977

Looks more like 75mm total.

The 55 in the Festool naming as in "Bit PH 2-AF-55 3x" refers to it's use in AF-55. AF-55 being the adapter for collated screws; supporting screws up to 55mm. The bits itself are marked as 152mm.

The better quality coarse ones I've found to be the best to drive into anything harder than pine, and are still only around $15AUD per carton. The fine thread ones snap really easily.What's our current feelings about buying screws for the Gun. As in, most available, commonly found., etc I still have some Festool stock ones as I never used this drywall gun as much as I thought I was going to when I bought it. But, when those run out... Would be Coarse Screws since I don't work with Steel Studs.

You never know what you get with Würth. They just use whatever is cheapest for them and supply it under their label. In fact, Würth re-supplied my employer... and the new bins included three different types of self-cutting bolts under the same article number...Würth

@six-point socket II I finally got a chance to look at my screw gun. The bit holder on mine looks pretty much the same as Oliver's. It seems to measure a little less than 3 inches - maybe 2 and 31/32 inches or around 75 mm. I was using a standard PH-2 Festool bit. Is there a different one for the DWC that's may be a little longer? Maybe it's user error on my part and I need to be more forceful. After putting it back together I tried it again and unless I really bear down, the screw is still a tiny bit proud. I have to back it out and drive it again to get it to seat properly.The bit holder that comes with the screw gun is a bit longer, did you accidentally swap that for another one?

Let me get a picture …

Kind regards,

Oliver

Previously, I've only used this tool to patch holes. Two of the houses (built in the mid 50's) had I think what was called "rock lath" (2' x 4' gypsum board) with plaster applied on top. I basically screwed in a piece of drywall into the patch and filled in with durabond or some other hot mud to roughly level with the surrounding plaster so getting the right dimple on the drywall patch really didn't matter as long as it was held in place.That is odd. Not aware of any ‘special’ DWC 25mm bit. I also have the standard Festool PH2 in mine currently. You can always try another one, but it really shouldn’t make a difference. Definitely looks like the correct bitholder!

If you get the screw seated properly the second time, you might have let go to early on the first drive. This does take a bit of force/ trust in the equipment to press down and let the machine do everything else until it stops. And you need to keep that force applied/ keep up with the speed of the screw gun.

Maybe tell us a bit more about what materials you are using?

Coen posted about an interesting case in post #25. This is also something to take into account - and !could! explain why your’s manages to seat the screw only in the second run, kinda like it utilizing the first run as ‘pre drill’ and only then managing to seat the screw properly because of ‘insufficient’ torque. (This is just thinking outside the box, and should not happen with metal studs or typical current softwood/ construction lumber.)

The only times I had not properly seated screws were in awkward positions when I couldn’t keep the force applied in line with the screw and/or keep up with the speed of the machine. Most of the time that is then accompanied by a ‘scream’ of the screw gun as the bit damages the screw head/drive.

I’d probably start with giving the screw gun a little workout on some scraps and get really used to it, just push down and keep up with the speed. If that then still results in not properly seated screws all/ most of the time, we need to asses further.

Kind regards,

Oliver