Packard

Member

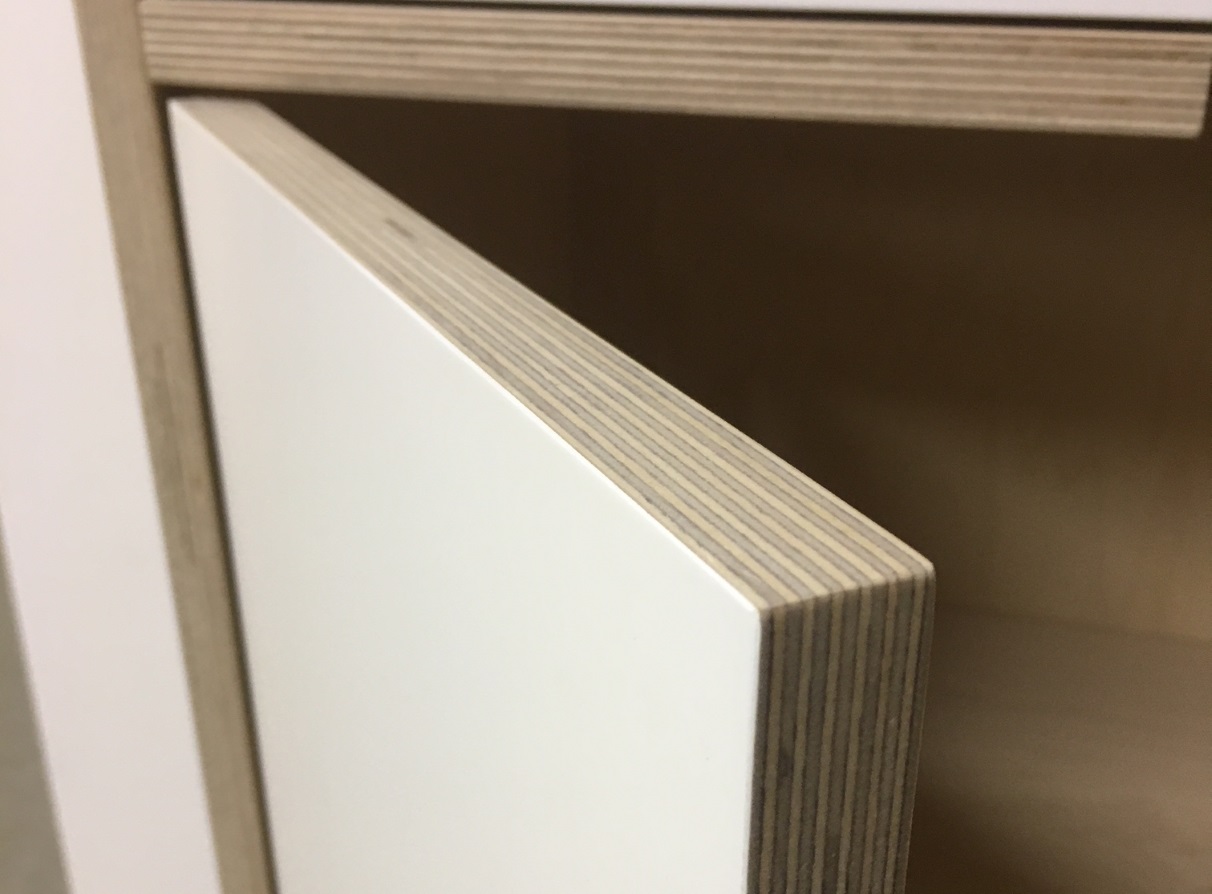

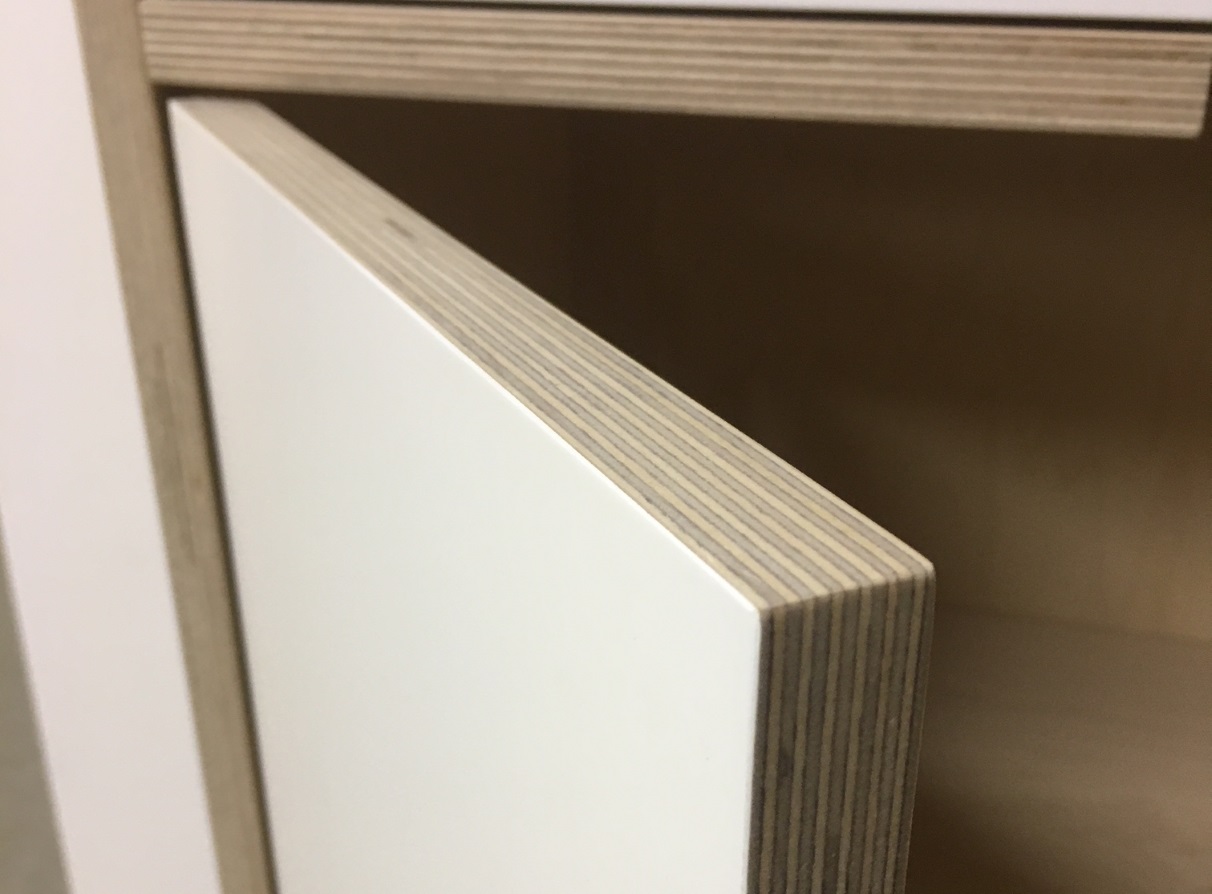

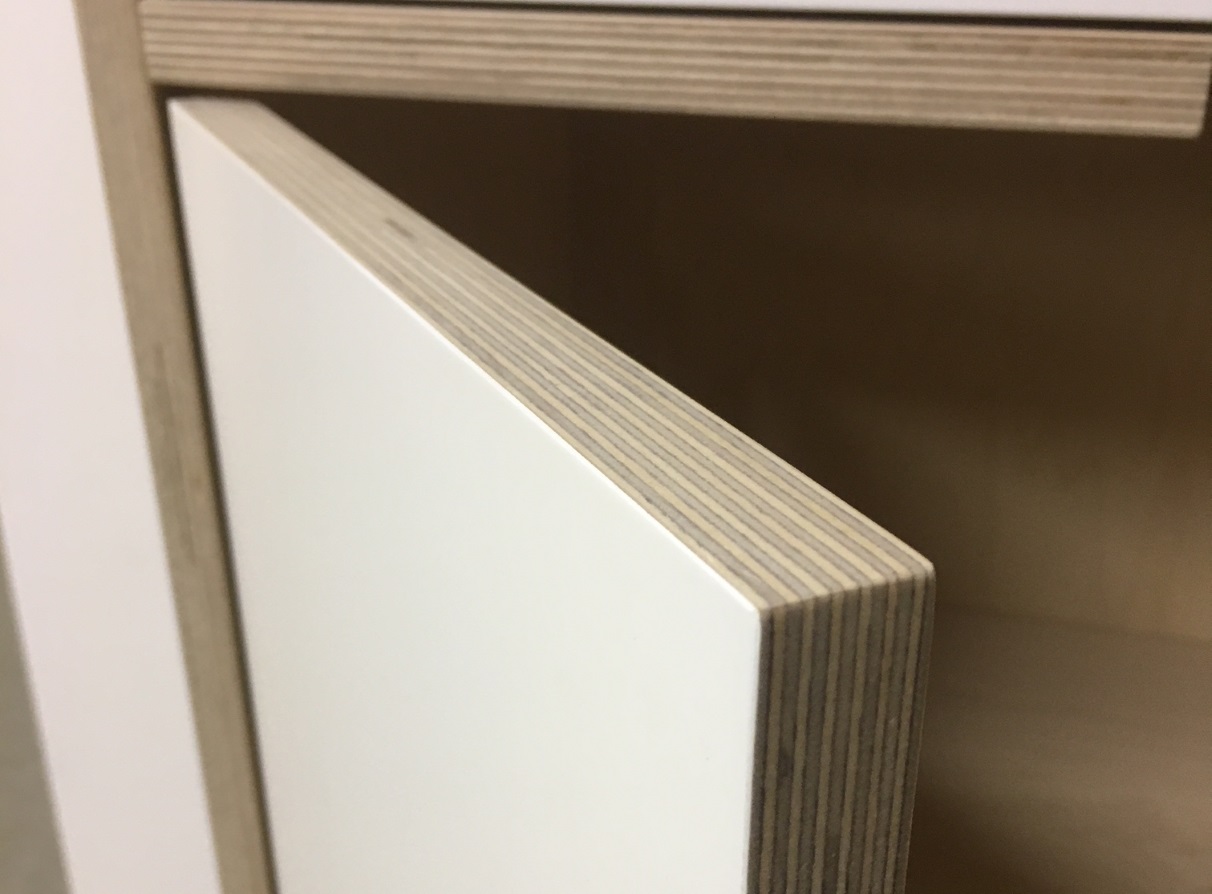

If you were building Baltic birch cabinets, would you edge band the doors or would you leave them "natural"? "Natural" would be faster, cheaper and probably more durable. And not a bad look.

clark_fork said:Vocation: Real Estate Appraiser

Advocation: Wood Worker

Advice: From Wood Worker-It is your house, make it work for you and the family. It is au courrant so up to-date in the market if not ahead of the market.

Advice: From Appraiser as to resale value: Limited pool of buyers at this time, too ahead of the market, too European. not ready for prime time.

Good points. I will keep that in mind.

Disclaimer: I am in Montana which some regard as not really comparable with the rest of the country. However, due to the pandemic and the rise in working from home, we are suffering an invasion from North California residents fleeing their State. "Build a wall" is being heard around the state. These folks would regret raw edges surprisingly. They want to return to what worked in the old days.

clark_fork said:Vocation: Real Estate Appraiser

Disclaimer: I am in Montana which some regard as not really comparable with the rest of the country. However, due to the pandemic and the rise in working from home, we are suffering an invasion from North California residents fleeing their State. "Build a wall" is being heard around the state. These folks would regret raw edges surprisingly. They want to return to what worked in the old days.

GoodBadUgly said:I am a rookie so pardon if it’s a silly question. Exposed look great but will it be treated to prevent absorption of any moisture, especially in a kitchen environment?

Baltic birch plywood in my workshop (garage) if left for a year, gets rough edges which I presume it is from wicking moisture.

Sent from my iPhone using Tapatalk