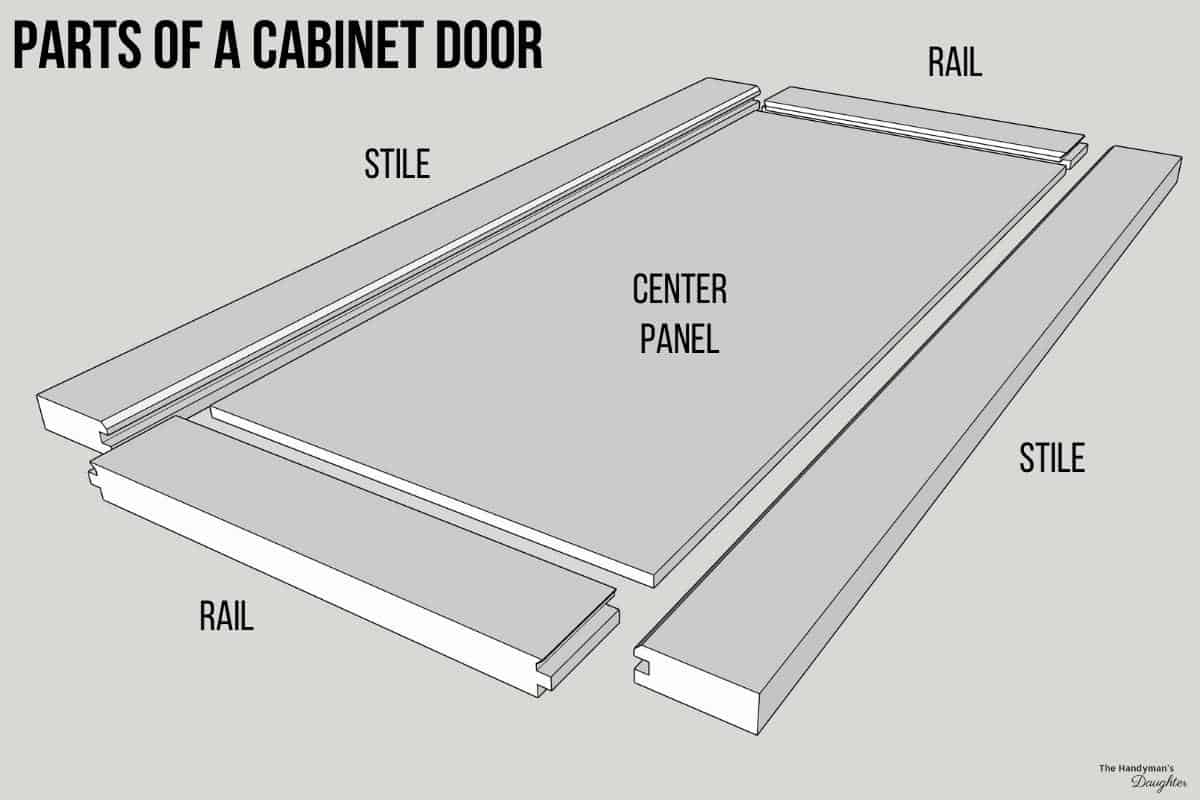

What is the best way to cut a 1/4" panel mortise in 3/4" quartersawn oak rails and stiles? I've used the table saw and a router table for rougher work in the past but both have drawbacks. In the requested design the rails are easy since the cut goes all the way through. But the stiles need the mortise to be stopped. Is this a case where the plexiglass routing aid (or equivalent) is best or ???

Best way to cut mortise in rail and stile

- Thread starter RonMiller

- Start date