Overtime

Member

- Joined

- Jan 25, 2007

- Messages

- 265

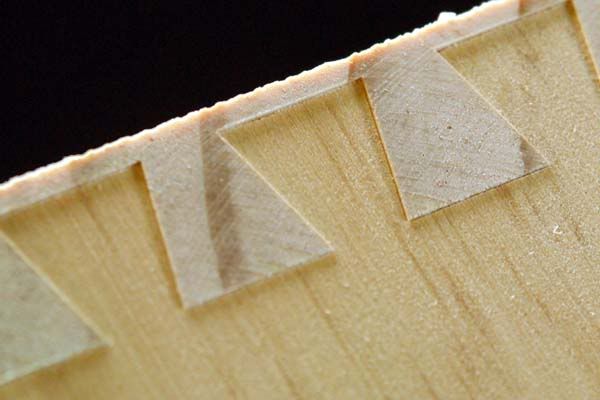

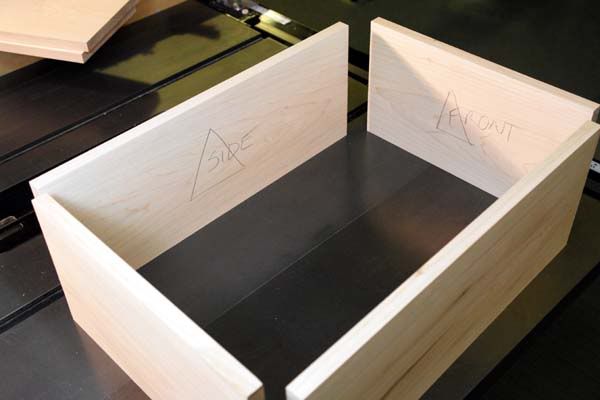

Let's make some Half Blind Dovetail drawers using some Festools along with a bunch of other fine woodshop machines and tools.

I'm making 6 drawers for two small cabinet base units.

Wood - American Soft Maple - drawer boxes

1/4" baltic birch ply - drawer bottoms

3/4" furniture grade ply - false fronts (drawer face) full overlay

Hardware - Blum

Cabinet type - Frameless 32mm (euro)

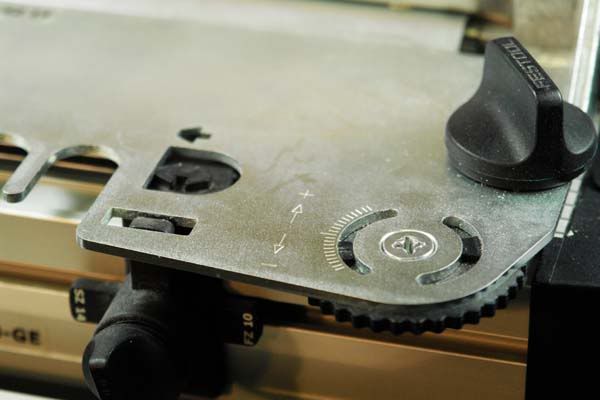

I will be using Festool's VS 600 Joining System and the OF 1010 to rout the dovetails.

Also featuring a combination of the metric and inch measuring systems ;D and 32mm system - LR 32

I'll cover the set up and use of the VS 600 using the SZ 14 template.

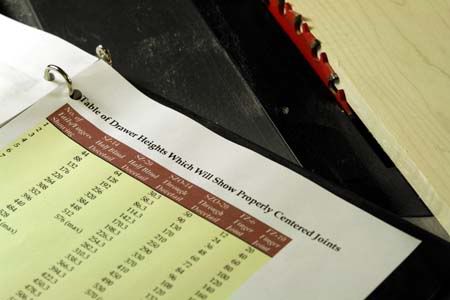

And we'll get a look at Blum's drawer hardware and drawer specs for installation.

I'm making 6 drawers for two small cabinet base units.

Wood - American Soft Maple - drawer boxes

1/4" baltic birch ply - drawer bottoms

3/4" furniture grade ply - false fronts (drawer face) full overlay

Hardware - Blum

Cabinet type - Frameless 32mm (euro)

I will be using Festool's VS 600 Joining System and the OF 1010 to rout the dovetails.

Also featuring a combination of the metric and inch measuring systems ;D and 32mm system - LR 32

I'll cover the set up and use of the VS 600 using the SZ 14 template.

And we'll get a look at Blum's drawer hardware and drawer specs for installation.