hi all,

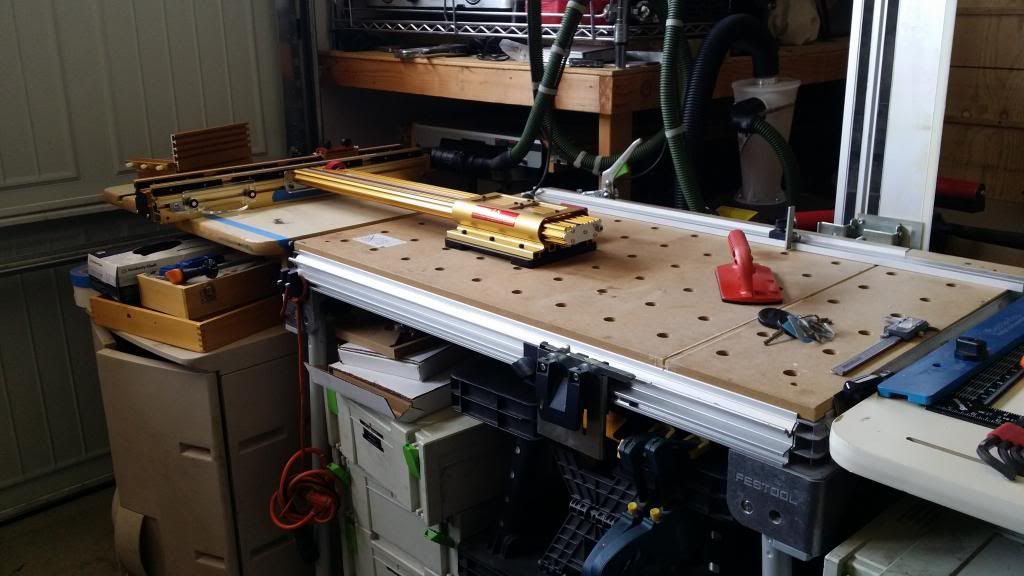

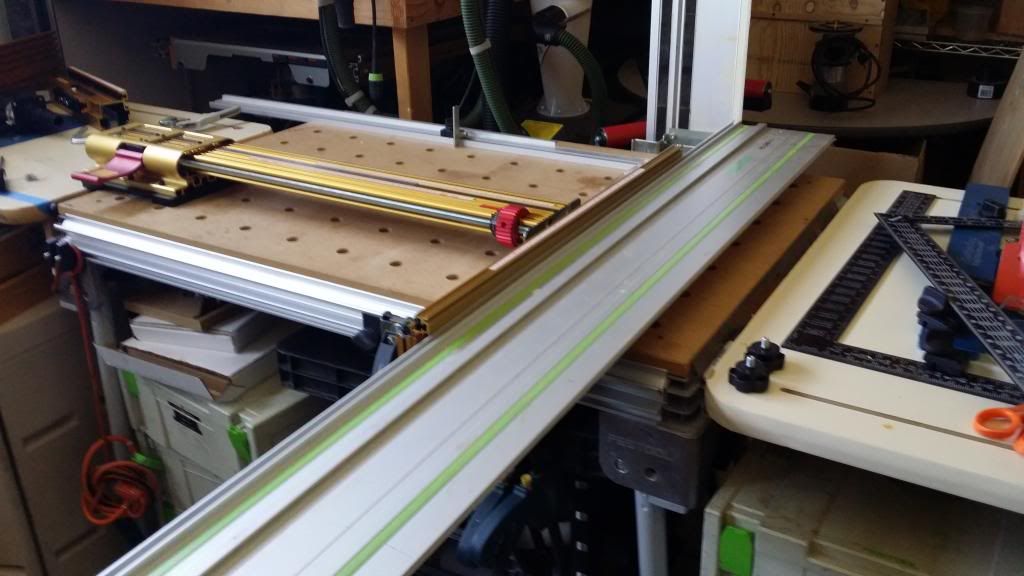

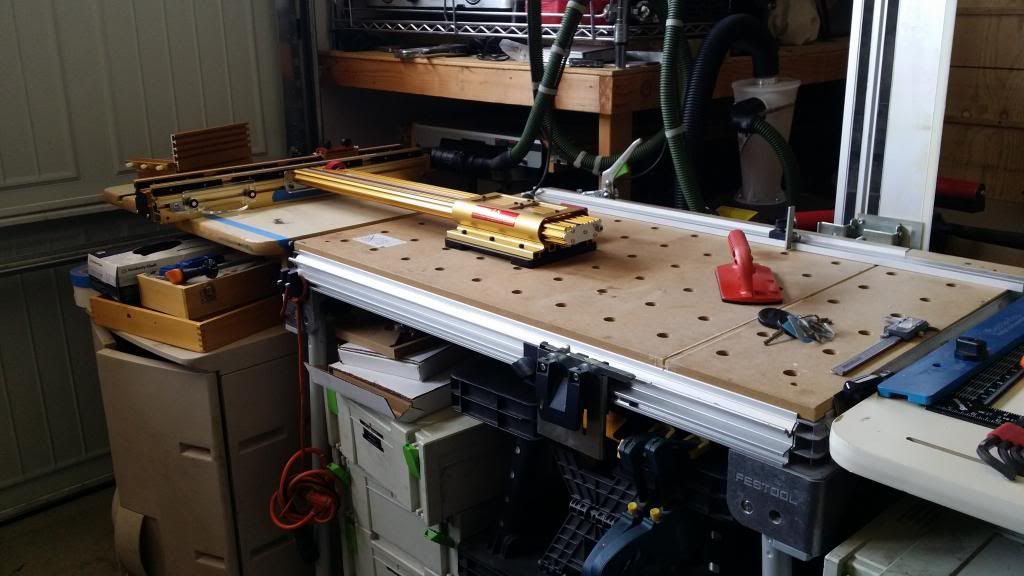

long time lurker here, first time poster. nothing revolutionary here, and quite a few others have already done this setup many times, but i haven't seen many pictures of this setup since precision dog's released their precision plate for the incra ls positioner so i figure i would post pics of my setup for anyone who is researching how to add the incra ls to their mft.

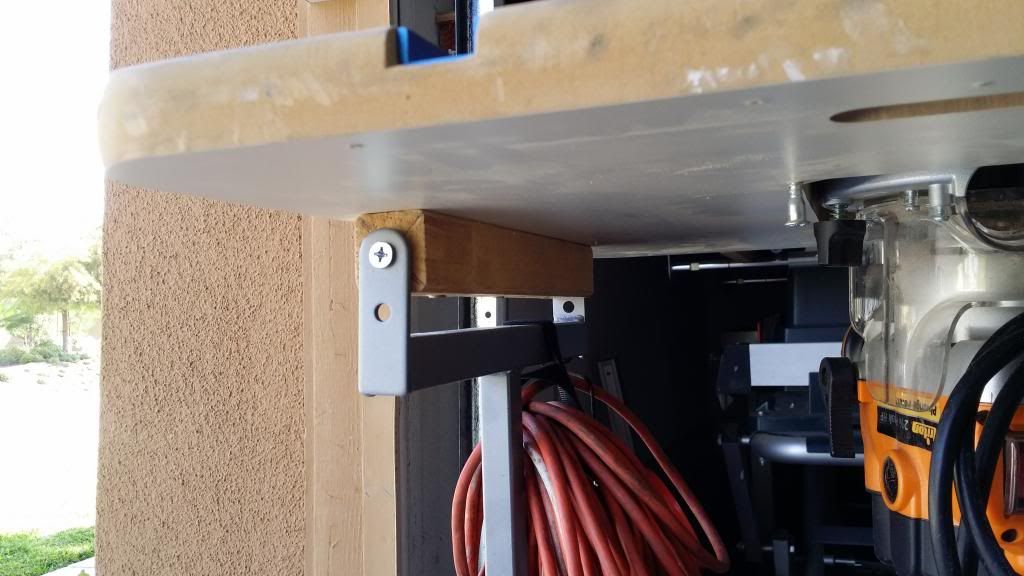

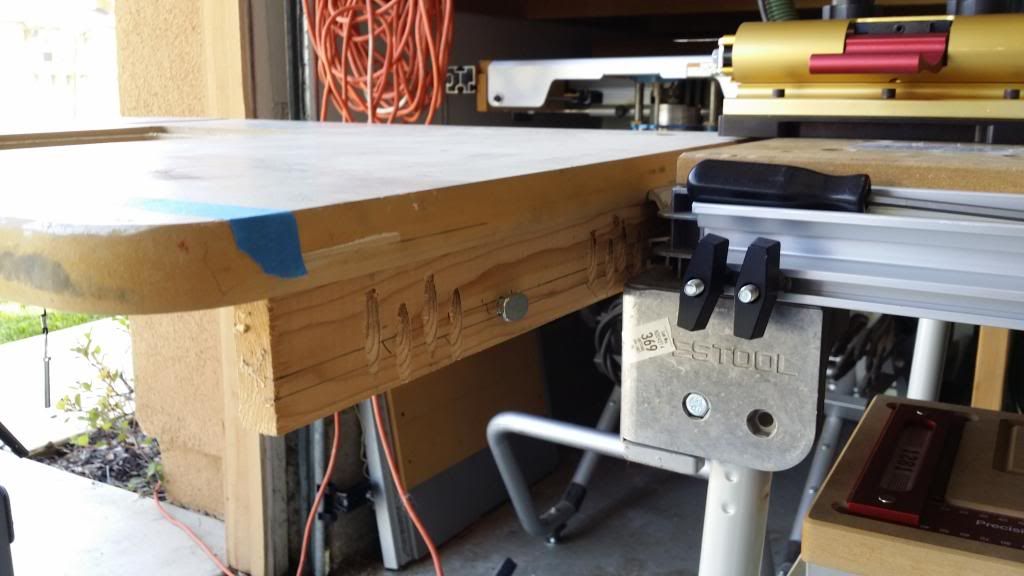

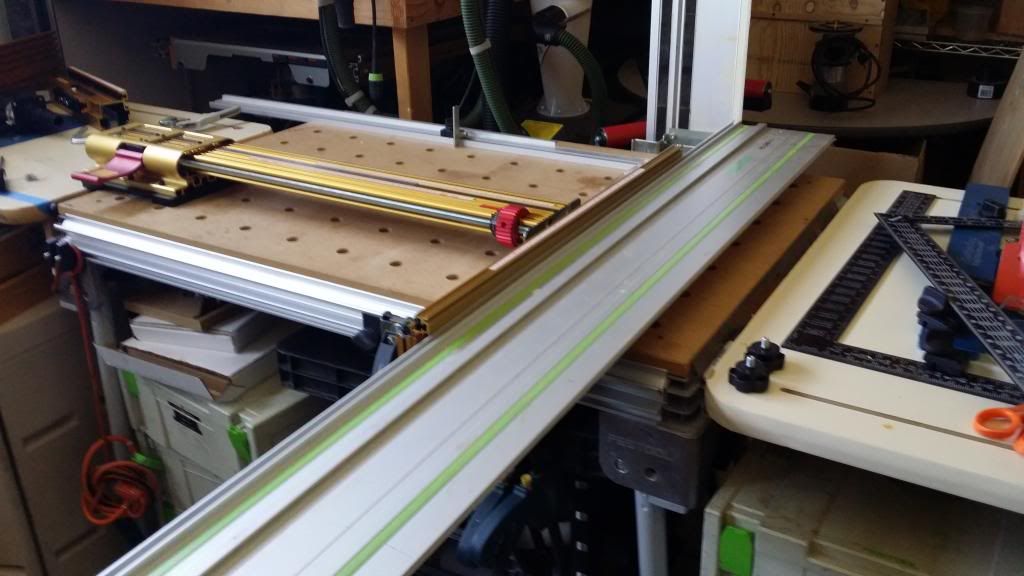

i just used simple t-bolts to add 2 rockler router tables to the mft (one on each side). other side of the router table have the adjustable leg system from the rigid flip top stand to level out the router table to the mft top. the v grooves are still exposed and i use them as pencil trays. this keeps everything still mobile if i need to move it anywhere.

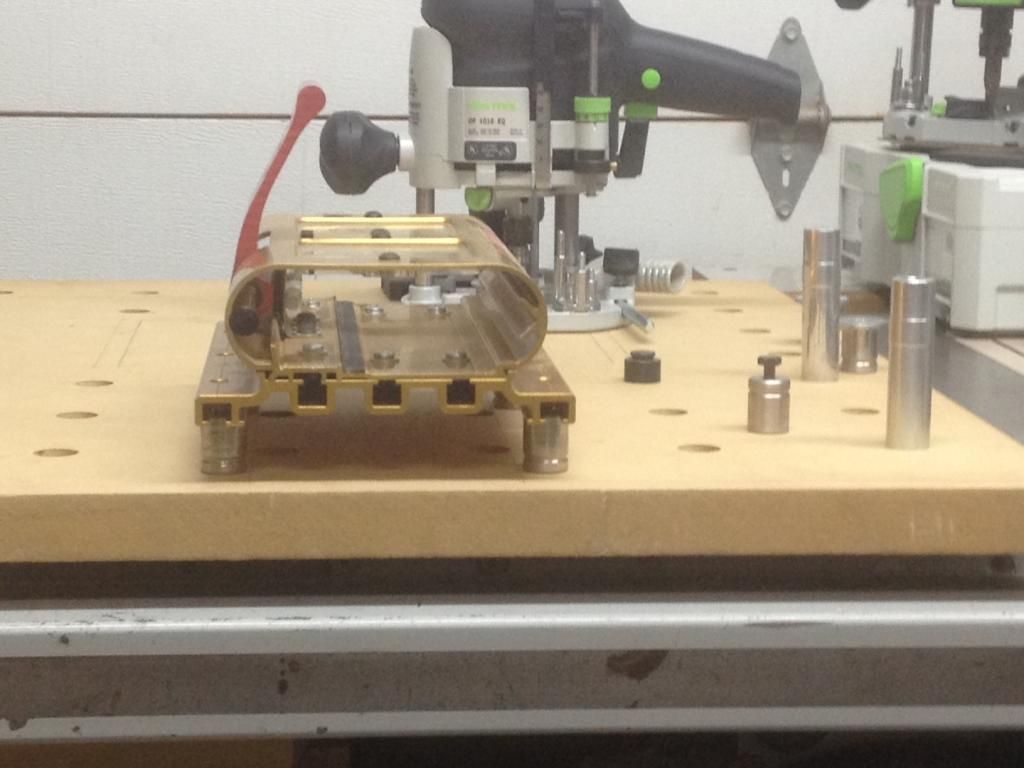

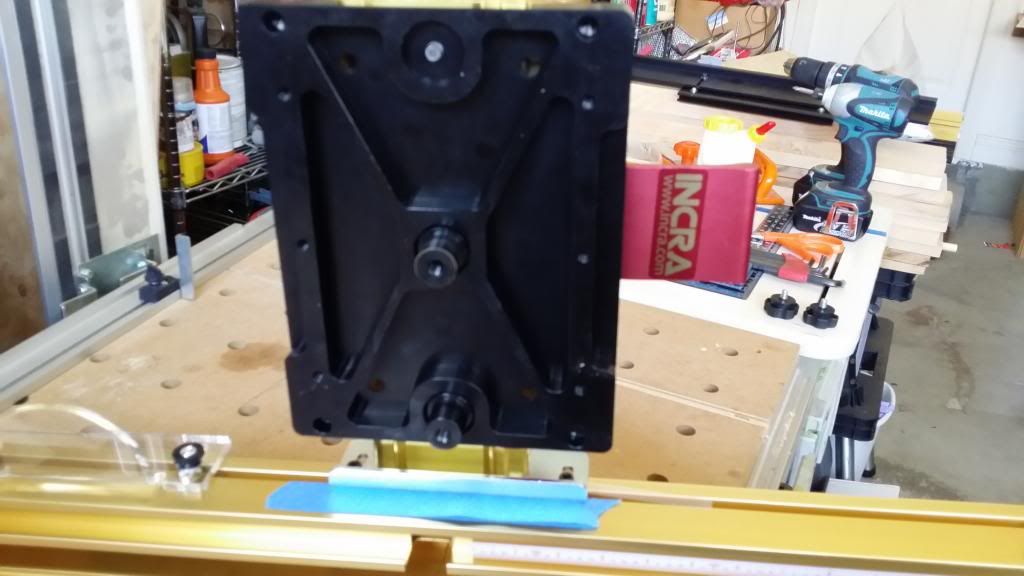

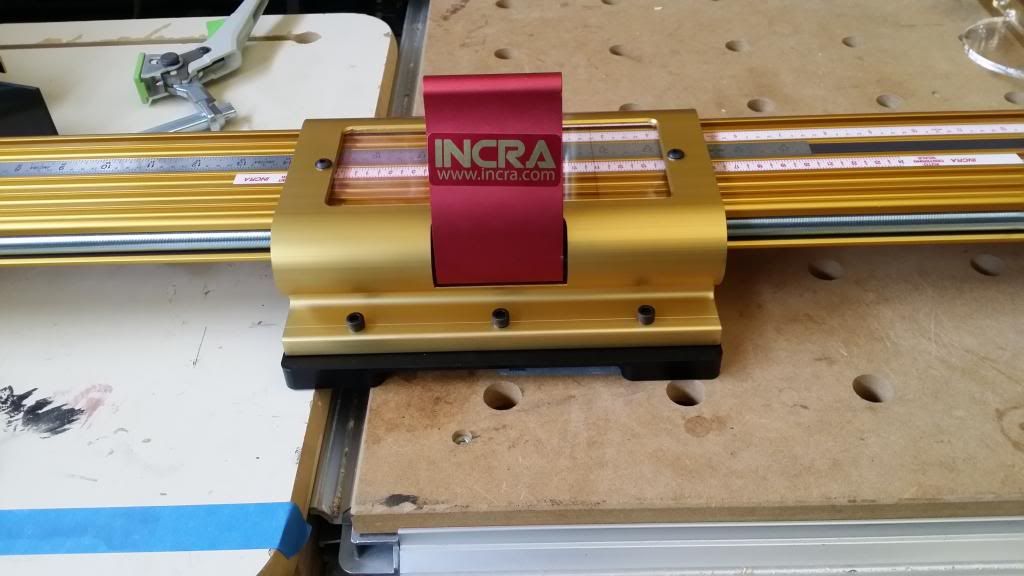

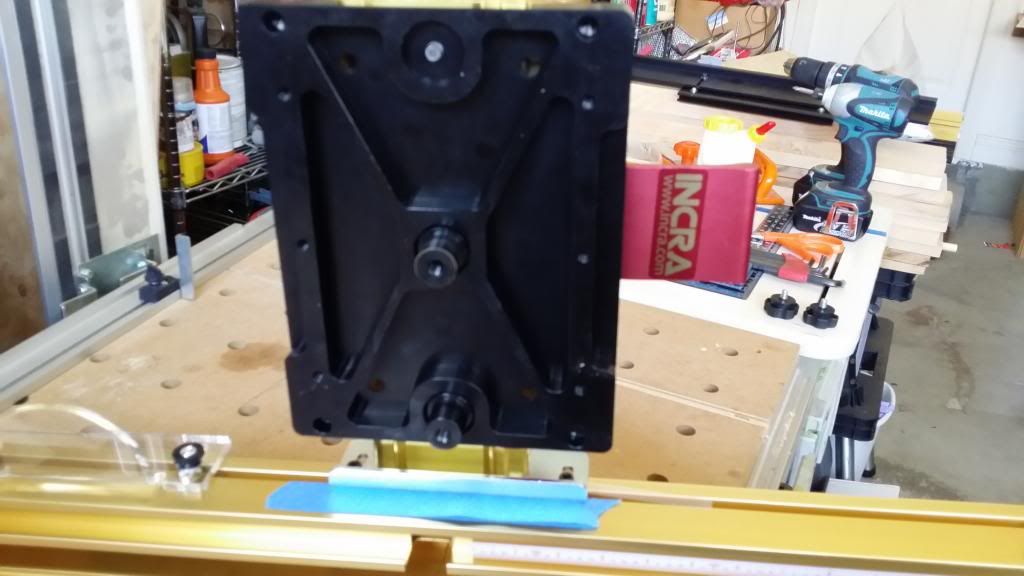

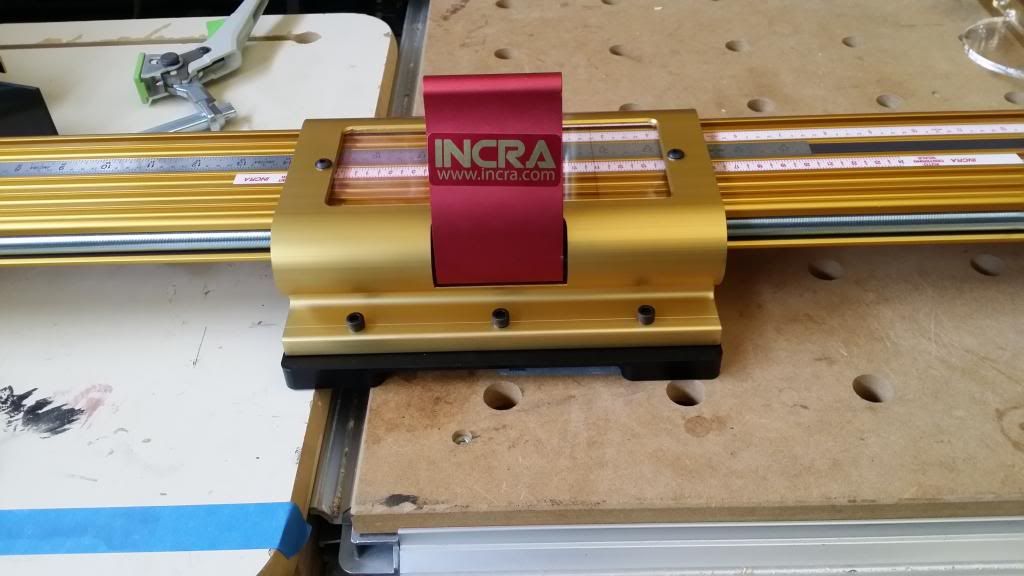

the incra ls positioner base is mounted to the precision plate. i used 2 adjacent positions for the mounting dogs instead of the 2 far ones. reason being is when i flip the ls position to face the cutting rail, i can place it as far to the edge of the table as i can to get the maximum rip distance. then i can add a spacer block under the cutting rail to cut thin strips with incra's accruracy and repeatability with the thin strip under the cutting rail where it can't move at all.

i just need to move the mounting dog under the rail to the other side to use it for the ts55.

quick measurements were:

using the factory rail location, i get ~23 1/2" cutting capacity and the convenience of just flipping the rail up out of the way.

using my parf dogs to set the rail, i get ~28 13/16" cutting capacity but the dogs are in the way.

using my rail dogs to set the rail, i get ~29 13/16" cutting capacity. i could move the factory rail location to here to match since i have my other router table mounted level and useable as extra table for cutoffs.

all measurements were re-zeroed to include the width of the rail (7 1/4")

extremely happy with this setup!

long time lurker here, first time poster. nothing revolutionary here, and quite a few others have already done this setup many times, but i haven't seen many pictures of this setup since precision dog's released their precision plate for the incra ls positioner so i figure i would post pics of my setup for anyone who is researching how to add the incra ls to their mft.

i just used simple t-bolts to add 2 rockler router tables to the mft (one on each side). other side of the router table have the adjustable leg system from the rigid flip top stand to level out the router table to the mft top. the v grooves are still exposed and i use them as pencil trays. this keeps everything still mobile if i need to move it anywhere.

the incra ls positioner base is mounted to the precision plate. i used 2 adjacent positions for the mounting dogs instead of the 2 far ones. reason being is when i flip the ls position to face the cutting rail, i can place it as far to the edge of the table as i can to get the maximum rip distance. then i can add a spacer block under the cutting rail to cut thin strips with incra's accruracy and repeatability with the thin strip under the cutting rail where it can't move at all.

i just need to move the mounting dog under the rail to the other side to use it for the ts55.

quick measurements were:

using the factory rail location, i get ~23 1/2" cutting capacity and the convenience of just flipping the rail up out of the way.

using my parf dogs to set the rail, i get ~28 13/16" cutting capacity but the dogs are in the way.

using my rail dogs to set the rail, i get ~29 13/16" cutting capacity. i could move the factory rail location to here to match since i have my other router table mounted level and useable as extra table for cutoffs.

all measurements were re-zeroed to include the width of the rail (7 1/4")

extremely happy with this setup!