I'm a cabinet maker. I have many Festool tools and find most of them to be excellent and huge time savers (which makes me money). I have thought about getting a kapex for a long time. My hesitation on the Kapex has always been the cut capacity.

For comparison purposes: Prior to the Kapex I had 4 miter saws. They are a Dewalt 12" slider retrofitted with the shadow light, a Bosch 12" axial glide that stays in the shop, a Hitachi 12" non slider and a Porter cable 10" for small jobs and easy transport. I now have 5 miter saws.

I was lucky enough to get a Kapex on the recon site. I was pleased when it arrived as if you told me it was brand new I would believe it.

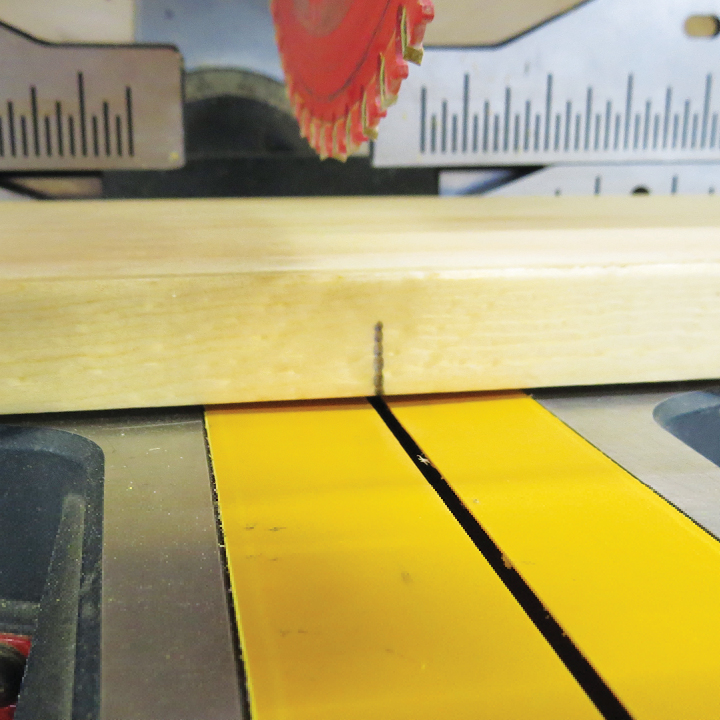

I have used the Kapex for a few days now and I can say that it is the most refined, smoothest operating saw I own. I have been using it to cut the face frames for a full kitchen job.

The good:

Soft start is fantastic

Dual lasers are great (I prefer them to the shadow line)

My kapex has absolutely no play it miters and slides straight down ( the Bosch has loads of play and the DeWalt has some)

The bevel controls are a game changer. It is night and day compared to any of the saws I own (Hitachi is a nightmare and the others are inconvenient)

Lightest of the sliders I own.

Negatives:

Capacity. (Both my DeWalt and Bosch will cut to 14").

Dust collection ( only because I expected it to be better. It is better than the DeWalt and no better than the Bosch)

Angle doohickey (useless for my proposes. I measure whole rooms and record the lengths and angles. Measuring one angle at a time does not help me at all)

Table size. I added the crown stops and they increase the table size nicely, but out of the box the table is rather anemic.

Having said all this I really enjoy using the saw. I paid around $1200 delivered. All my tools are insured and if it came up missing I would buy another. I will use it for parts of jobs that required tolerances down to a 1/32" anywhere else will get the DeWalt.

All in all if you are looking for extreme accuracy ( there really is zero play) in a smooth and pleasing to operate saw the Kapex may be for you.

If you have questions, let me know.

For comparison purposes: Prior to the Kapex I had 4 miter saws. They are a Dewalt 12" slider retrofitted with the shadow light, a Bosch 12" axial glide that stays in the shop, a Hitachi 12" non slider and a Porter cable 10" for small jobs and easy transport. I now have 5 miter saws.

I was lucky enough to get a Kapex on the recon site. I was pleased when it arrived as if you told me it was brand new I would believe it.

I have used the Kapex for a few days now and I can say that it is the most refined, smoothest operating saw I own. I have been using it to cut the face frames for a full kitchen job.

The good:

Soft start is fantastic

Dual lasers are great (I prefer them to the shadow line)

My kapex has absolutely no play it miters and slides straight down ( the Bosch has loads of play and the DeWalt has some)

The bevel controls are a game changer. It is night and day compared to any of the saws I own (Hitachi is a nightmare and the others are inconvenient)

Lightest of the sliders I own.

Negatives:

Capacity. (Both my DeWalt and Bosch will cut to 14").

Dust collection ( only because I expected it to be better. It is better than the DeWalt and no better than the Bosch)

Angle doohickey (useless for my proposes. I measure whole rooms and record the lengths and angles. Measuring one angle at a time does not help me at all)

Table size. I added the crown stops and they increase the table size nicely, but out of the box the table is rather anemic.

Having said all this I really enjoy using the saw. I paid around $1200 delivered. All my tools are insured and if it came up missing I would buy another. I will use it for parts of jobs that required tolerances down to a 1/32" anywhere else will get the DeWalt.

All in all if you are looking for extreme accuracy ( there really is zero play) in a smooth and pleasing to operate saw the Kapex may be for you.

If you have questions, let me know.