Neil Lickfold

Member

Hi all,

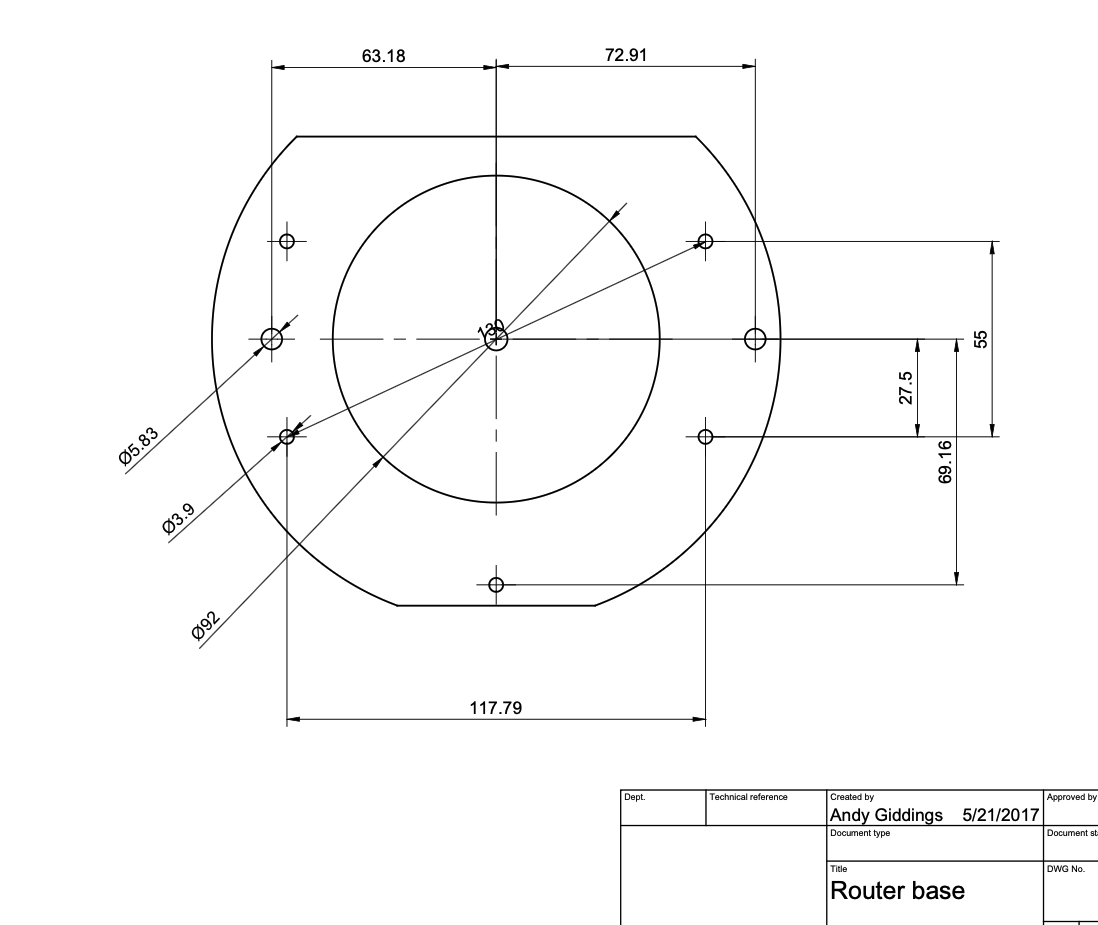

Does anyone know if a round base is available for the OF1400 router? I want to use the router inside a frame, and don't want to be using the copy rings. The flats on the sides of the current base is a pain, and don't want to go and buy another router for this one job. Rather buy a round base insert. If one is not available will make one.

Does anyone know if a round base is available for the OF1400 router? I want to use the router inside a frame, and don't want to be using the copy rings. The flats on the sides of the current base is a pain, and don't want to go and buy another router for this one job. Rather buy a round base insert. If one is not available will make one.