Guy Ashley

Member

- Joined

- Feb 19, 2010

- Messages

- 662

I have the Leigh D4R Dovetail Jig and have used it with my previous 1/2" router without any problems.

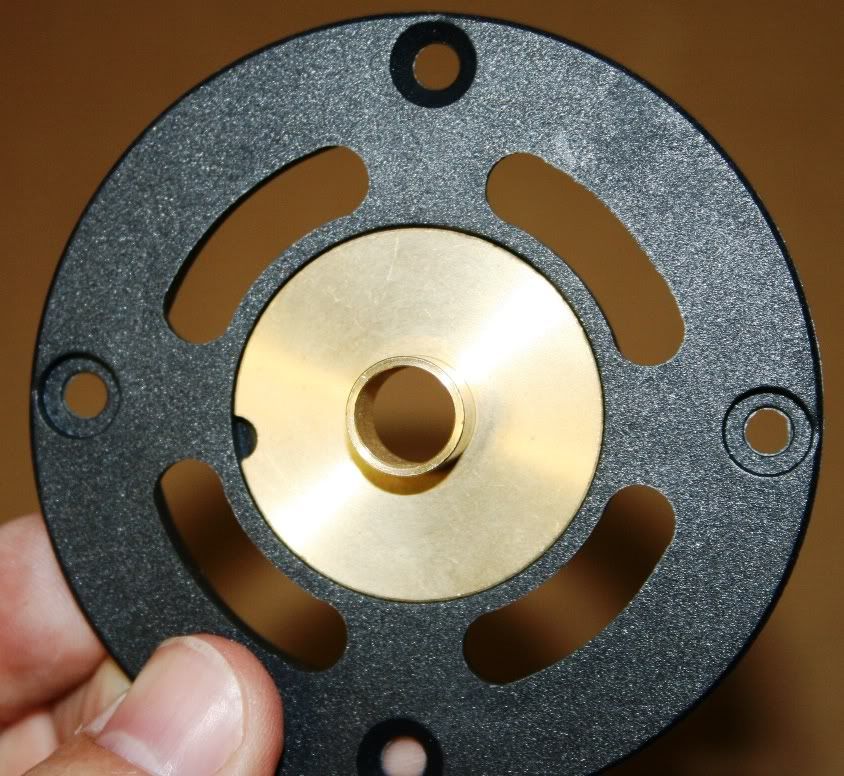

I have also the OF2200 and have recently done a test drawer using the KRA-ZOLL/OF2200 Adaptor

In the UK we have to purchase from Leigh a 711TP and 716TP threaded guidebush to affix to the KRA-ZOLL/OF2200 adaptor to make the system work.

I understand from the Leigh Industries website that these guidebushes are supplied as standard in the US when you purchase the Leigh Jig.

However on using these guide bushes with the KRA-ZOLL/OF2200 adaptor I find there is a good 1mm of play and it is impossible to keep the guide bush centered and so the cut dovetails are out of true and there are awful gaps in the pins and tails.

Anyone else had this problem?

I have not contacted Leigh Industries yet in case there is a simple resolution to this issue so any advice would be appreciated.

Guy

I have also the OF2200 and have recently done a test drawer using the KRA-ZOLL/OF2200 Adaptor

In the UK we have to purchase from Leigh a 711TP and 716TP threaded guidebush to affix to the KRA-ZOLL/OF2200 adaptor to make the system work.

I understand from the Leigh Industries website that these guidebushes are supplied as standard in the US when you purchase the Leigh Jig.

However on using these guide bushes with the KRA-ZOLL/OF2200 adaptor I find there is a good 1mm of play and it is impossible to keep the guide bush centered and so the cut dovetails are out of true and there are awful gaps in the pins and tails.

Anyone else had this problem?

I have not contacted Leigh Industries yet in case there is a simple resolution to this issue so any advice would be appreciated.

Guy