pingvinlakrits

Member

- Joined

- Oct 2, 2007

- Messages

- 1,093

I actually like the Power Hub/Sys, it rides along with the Festool MIDI, always on top.

I don't really like the power cord as it is unnecessary bulky and I decided to swap it out for a same length, same gauge (of course) but with another type of shielding/cover. The cord I opted for is much easier to roll up, takes up less space and is easier to clean as well. It is oil and chemical resistent.

I know this voids warranty but I am sure it won't suddenly fail on me. It isn't that complicated a design. I am not encouraging anyone to do as I did either, this was simply my choice.

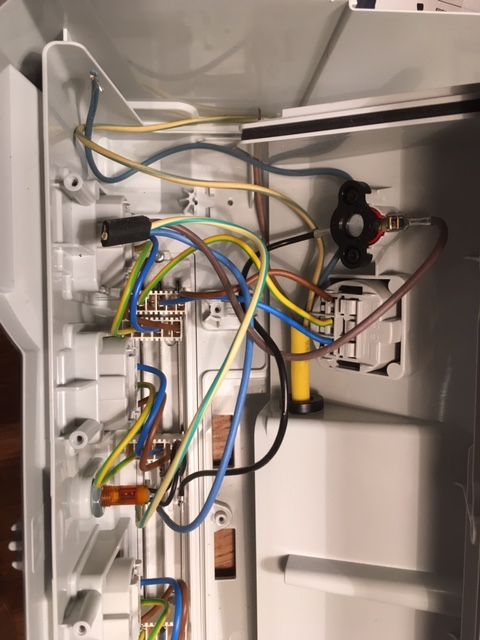

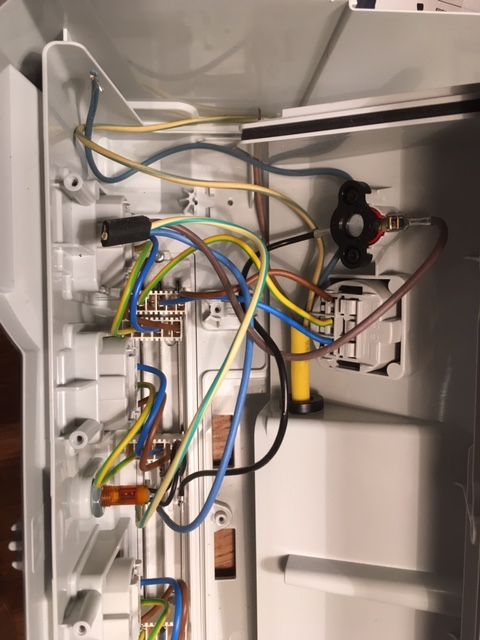

Opening up the power sys/hub was straight forward as was the connections, easy to rout the cables and fit them with the same type connectors as the original. In this photo the older cable is still in there so I make sure I fit the cables in the same place. Not a problem since the color coding is according to European standard for Live/Ground/Neutral but it is easy to forget what end goes where since there are empty slots in the rack connector.

It looks like the festool cord has _four_ strands in the first picture, but it has three.

New cable in place:

More room!

SYS-Rock in place. Sys Lite is in there too but was in use during the operation. Both the SYS Lite and the SYS Rock fits easily with the replacement cord. There is still place for some sundries if needed. With the original power cord there was hardly room to fit the SYS Rock and SYS Lite without some rummaging around.

Next thing I did was to cut down the MIDI vac cord [eek] as I don't plan on leaving the Power Hub behind and the vac + operating a machine works fine. I left the cord just long enough to reach the first two outlets. No more rolling up the vac cord [smile] only the power hub cord to roll up which of course still needs to be done.

It has been used for two months in this configuration and it works flawlessly with all tools tested and hooked up to the vac and running through the Power Hub for hours on end.

A simple hack but it has made it a little easier on site. The best thing with cutting the Vac cord is that the vac hose does not have to compete with the power cord for space in the hose garage. Also, work space is a lot less cluttered without having two long cords lying around.

I don't really like the power cord as it is unnecessary bulky and I decided to swap it out for a same length, same gauge (of course) but with another type of shielding/cover. The cord I opted for is much easier to roll up, takes up less space and is easier to clean as well. It is oil and chemical resistent.

I know this voids warranty but I am sure it won't suddenly fail on me. It isn't that complicated a design. I am not encouraging anyone to do as I did either, this was simply my choice.

Opening up the power sys/hub was straight forward as was the connections, easy to rout the cables and fit them with the same type connectors as the original. In this photo the older cable is still in there so I make sure I fit the cables in the same place. Not a problem since the color coding is according to European standard for Live/Ground/Neutral but it is easy to forget what end goes where since there are empty slots in the rack connector.

It looks like the festool cord has _four_ strands in the first picture, but it has three.

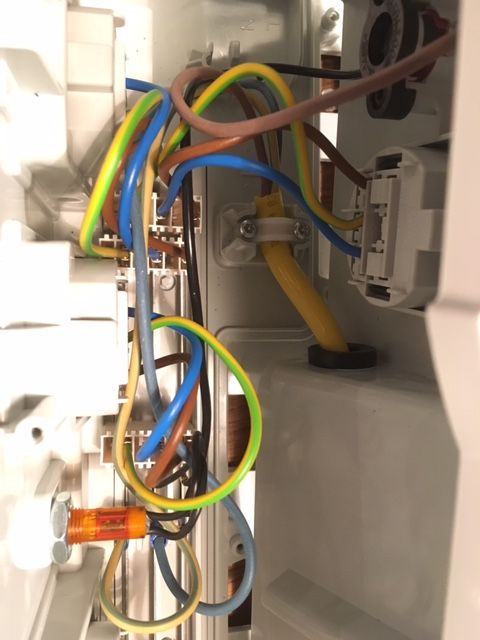

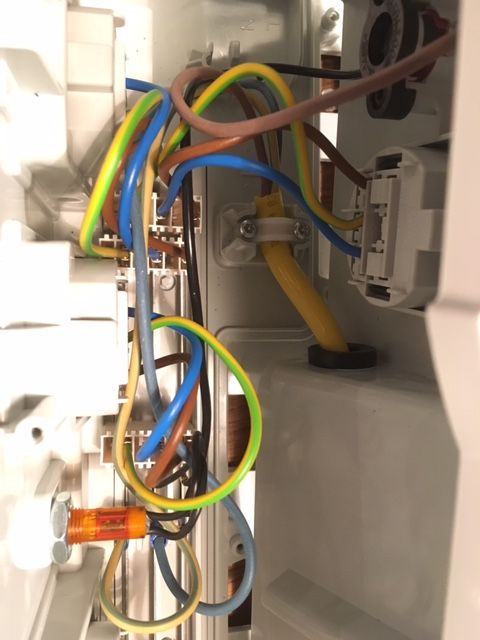

New cable in place:

More room!

SYS-Rock in place. Sys Lite is in there too but was in use during the operation. Both the SYS Lite and the SYS Rock fits easily with the replacement cord. There is still place for some sundries if needed. With the original power cord there was hardly room to fit the SYS Rock and SYS Lite without some rummaging around.

Next thing I did was to cut down the MIDI vac cord [eek] as I don't plan on leaving the Power Hub behind and the vac + operating a machine works fine. I left the cord just long enough to reach the first two outlets. No more rolling up the vac cord [smile] only the power hub cord to roll up which of course still needs to be done.

It has been used for two months in this configuration and it works flawlessly with all tools tested and hooked up to the vac and running through the Power Hub for hours on end.

A simple hack but it has made it a little easier on site. The best thing with cutting the Vac cord is that the vac hose does not have to compete with the power cord for space in the hose garage. Also, work space is a lot less cluttered without having two long cords lying around.