Greetings and Happy Holidays Festoolians-

I have a basic question about sanding face frames flush.... so I thought I'd see how you pros do it.

When I assemble a face frame, I do my best to keep things flush on the show side, but inevitably things are off a little bit.

Usually I hand sand with 80-grit to level the rails, and accepting any cross-grain scratches that appear in the stiles.

Then I hand-sand the stiles to remove the cross-grain scratches, avoiding the rails.

Then random-orbit sand the entire surface, going through the grits.

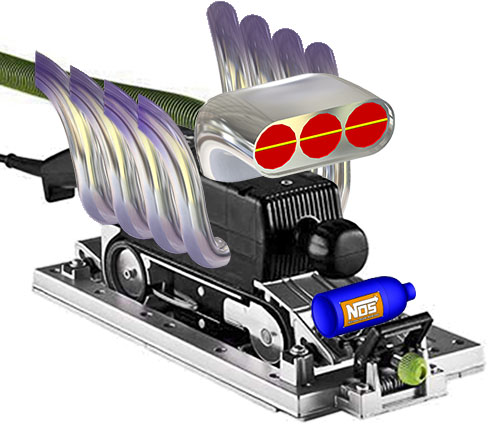

FWIW I have an ETS125 available as well as an ancient hand-held belt sander.

Any suggestions or feedback on a better way to do it would be appreciated!

-Tom in SoCal

I have a basic question about sanding face frames flush.... so I thought I'd see how you pros do it.

When I assemble a face frame, I do my best to keep things flush on the show side, but inevitably things are off a little bit.

Usually I hand sand with 80-grit to level the rails, and accepting any cross-grain scratches that appear in the stiles.

Then I hand-sand the stiles to remove the cross-grain scratches, avoiding the rails.

Then random-orbit sand the entire surface, going through the grits.

FWIW I have an ETS125 available as well as an ancient hand-held belt sander.

Any suggestions or feedback on a better way to do it would be appreciated!

-Tom in SoCal