No, the forward/reverse switch is entirely electronic with a neodymium magnet that the control board senses to tell it which direction to turn. There is no interlock and the switch does not connect to anything.

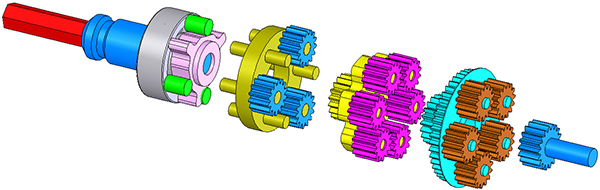

I never understood the original question so I did not respond previously. If the drill is rotating while tightening the chuck, then the shaft lock pins are not engaging. These are the 3 green pins in the image below. When the motor is driving the output shaft, these pins are held in the center of a detent area and allow movement. However, when the output shaft is turning the transmission, these pins move out of the detent area and jam between the pink colored lobes and the gear housing.

There are two situations where these pins will not function as well as they should. The first one is having too much grease in the gearbox. I learned this because I mistakenly added grease to my gearbox when I reassembled it. On my older C-12 this added grease causes the chuck to make a full revolution before the pins engage.

The second cause would be from over torquing the output shaft and damaging the pink colored lobes shown below, or the transmission housing. I have heard of some people that wanted to compare the power of two different drills by chucking them both together to have a "tug of war". If you do this with a Festool drill, you will likely destroy the Festool transmission and possibly burn out the other drill.

Once these pins engage, you cannot turn the output shaft. If you turn the output shaft hard enough to overcome this mechanism, you probably have damaged your drill (sorry Brice).