Mini Me mentioned that

@derekcohen likely had a bandsaw blade sharpening jig. I do seem to remember that, too. So this reply is a bat-signal to see if Derek has some fine words about this.

Hi Paul

The article is here:

https://www.inthewoodshop.com/Powered Tools and Machinery/SharpeningBandsawBlades.html

Copy-and-paste from my website:

I was asked to explain how I go about sharpening my bandsaw blades, and finally got around to putting together a couple of photos.

Let me say first that I did not invent this method. It is widely used. I learned it on YouTube, that font of all important wisdom

The fixture is new, and really thrown together in about 20 minutes. Before this, for a number of years, I would simply freehand this process. That worked well. Eventually .. recently .. I decided a fixture would offer more reliable results and less hand fatigue. Well, I think that this is so.

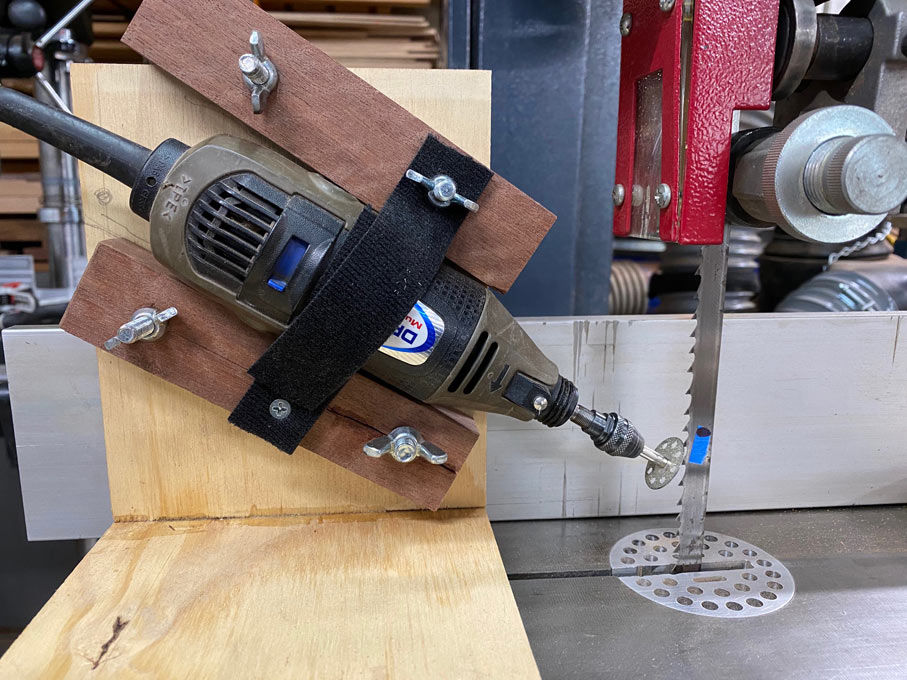

The main tool is a Dremel with a small diamond disk (the disks are available for pennies on eBay).

The blade here is bimetal 3 tpi 10mm wide. These are easy to sharpen. I use these blades for most everything except re-sawing wide boards.

I have also very successfully sharpened a 1.3 tpi 1" Lenox Woodmaster CT, which is a carbide tipped resaw blade.

The set up ...

This is made of two pieces of ply, at 90 degrees, the Dremel is wedged between the brackets at the desired angle, and held on with velcro straps ..

The method ...

Simply "touch" the back of the tooth and grind a teensy weensy flat. Damn these technical terms - not too complex I hope? The angle I choose is in line with the back, but it is not critical. What I believe that the fixture does (better than freehanding) is keep the height of the teeth the same. That ensures that all teeth are cutting.

Step 1. Mark the start of the blade (blue tape).

Step 2. Set the fixture against the bandsaw fence to keep it tracking square.

Step 3. Gently touch the wheel to the back of the tooth. Gently – enough to leave a silver flat.

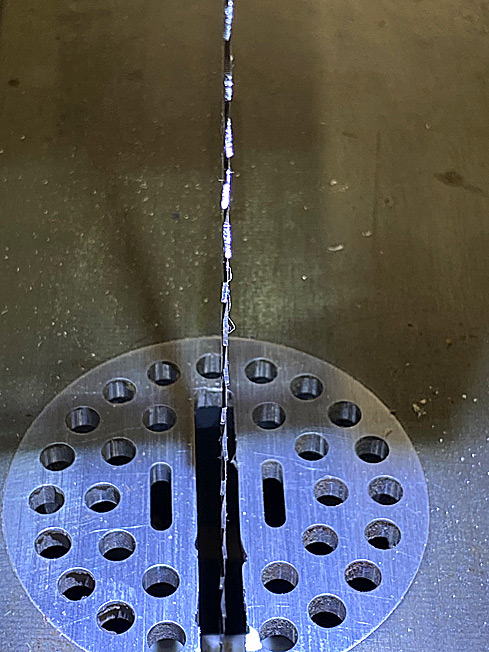

Below you can see (not too well, I'm afraid - the shiny spot looks the length of the tooth, which it is not) a tiny silver shine on the back of the teeth sharpened, and the absence of this on those unsharpened ... a better picture would resemble the sharpening of a backsaw ..

The result ...

The wood here is hard, dry Jarrah. The two sides are the result of cutting with a freshly sharpened blade.

Additional notes

Regarding matters such as indexing and sharpening the face vs back ...

I do not index - this method is as basic as it can be without doing it freehand. It is better than freehand, as the angle is consistent.

How long can it be done? I have used the freehand method for several years, and sharpened the 10mm bimetal blades about 5 times. Then I toss them. I would say that I have had my monies worth. The cut can get slightly smoother each time since there is fractionally less set with each sharpening.

What limits how long you can re-sharpen is, firstly, the size of the gullet - too small and it cannot carry away sawdust, and then it loads up and affects tracking. The second factor is the stiffness of the blade. Carbide blades are stiffer as they are thicker. They eventually fracture, and this is more common among bandsaws with smaller wheels, such as 14” (more bending). My Hammer has a roughly 18” wheel, and my last 1” Lenox Woodmaster CT, a carbide re-saw blade, disintegrated. It had been sharpened about 5 times.

Back vs front? Not much difference - both leave the bevel edge sharp by removing the wear bevel.

Here is a method (by Terry Gordon, from HNT Gordon tools) for sharpening the front. A guide is important as there is some risk that one may alter the cutting angle by sharpening the front if you do this freehand ...

The number of teeth come into the equation. Too many and it will take hours. The 10mm 3tpi bimetal blades take about 20-30 minutes. The 1.3 tpi 1” blades take about 10-15 minutes.

I leave the blade on the bandsaw - some like to do this task freehand on a bench grinder, and remove the blade to do so. Leaving the blade on the bandsaw makes it easier to keep the angle consistent ... and yet the bench grinder method still works well, which says that the sharpening is quite accomodating to angles. I do release some of the tension from the bandsaw, and work with the blade moving down. This is less tiring.

Regards from Perth

Derek

November 2020