You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

False Joint Set????????????

- Thread starter tallgrass

- Start date

As I understand it, the false joint set is used to do a sort of suspended ceiling. The panel(s) are installed on the ceiling, and then the saw is used to trim the edges, leaving a gap between the wall and the ceiling panel. Doing this in place makes it easier to deal with non-square rooms. I've seen this in Europe, but never in the USA.

Ned

Ned

The large black plastic thing covers the baseplate of the TS 55, giving it a smooth surface.

The brownish thing is also smooth, probably the same material as the router bases, and can be adjusted to various distances from, and parallel to, the blade.

Install the panel on the ceiling, but don't put fasteners or adhesive near the wall. Try to get the panel pretty close to the wall, but it doesn't have to touch.

Mount the False Joint Set on your saw. Adjust the depth of cut to just cut the panel. Adjust the guide for the desired distance from the wall.

Up you go, saw in hand. Turning the saw upside down, put the guide against the wall and trim the ceiling paneling to a uniform distance from the wall. Aren't you glad you have excellent dust collection?

Ned

Yeah, this doohickey is used to trim shadow lines in the ceiling. The difference between this and the parallel guide is that this references from the outside of the attachment, and the p guide references from the inside. The earlier post was spot on, it runs against the wall upside down.

Corwin said:Wouldn't you be able to do the same with the parallel guide. Is there any functional difference other that the base plate?

Europe chiming:

- looks like there is no star bolt to secure the parallel edge

- it also seems that the edge can be rotated, allowing the saw to rest on a non vertical wall

while the edge rests on an horizontal ceiling

- The smooth plastic may slide better than the base plate and the parallel guide

dirtydeeds

Member

- Joined

- Nov 22, 2007

- Messages

- 1,009

false joints are just another way of hiding discepancies in trim, it is more used on the continent

we all leave a reveal between a door lining and architrave (casing)

we sometimes install plinth blocks at the bottom of doors to butt skirting (baseboard) and architrave so that dfferential movement is hidden

some timber and plaster coving (crown) has a rolled edges which helps hide wall and ceiling discrepancies, this we call a shaddow gap

the false joint does the same job, it creates a shaddow gap

we all leave a reveal between a door lining and architrave (casing)

we sometimes install plinth blocks at the bottom of doors to butt skirting (baseboard) and architrave so that dfferential movement is hidden

some timber and plaster coving (crown) has a rolled edges which helps hide wall and ceiling discrepancies, this we call a shaddow gap

the false joint does the same job, it creates a shaddow gap

Thanks to mhch, DD, and that voluntary foreigner, Eli!

Now that we understand what the thing does, could it be used to do anything else? Something that might cause someone in North America to want this accessory?

If this thread causes 3 False Joint Sets to be sold by Festool USA, that would probably be a 300% increase.

Ned

Now that we understand what the thing does, could it be used to do anything else? Something that might cause someone in North America to want this accessory?

If this thread causes 3 False Joint Sets to be sold by Festool USA, that would probably be a 300% increase.

Ned

dirtydeeds

Member

- Joined

- Nov 22, 2007

- Messages

- 1,009

i cant provide a picture

but can provide an example of a shaddow gap used by carpenters around the world on a daily basis

shooting in a door so it has a 2mm margin all the way round is a shaddow gap

it tricks the eye into seeing an equal margin even if the door and lining arnt perfectly plumb to each other

but can provide an example of a shaddow gap used by carpenters around the world on a daily basis

shooting in a door so it has a 2mm margin all the way round is a shaddow gap

it tricks the eye into seeing an equal margin even if the door and lining arnt perfectly plumb to each other

dirtydeeds

Member

- Joined

- Nov 22, 2007

- Messages

- 1,009

tallgrass

second fix carpentry (trim) works on the same basis worldwide, it is a trick of the eye

a shaddow or reveal (that causes a shaddow) hides discrepancies by tricking the eye to see something else

but it is another way for second fix carpenters to "see / deal " with a problem

i work in english buildings of ages between 50 and 500 years old that have seen (and will continue to see) a lot of movement

since seeing the false joint tool in the uk festool catalog 2006 i have incorporated the technique into my reportiure

i have used a combination of scribing and 45 degree beveling (to create a shaddow gap) to good effect

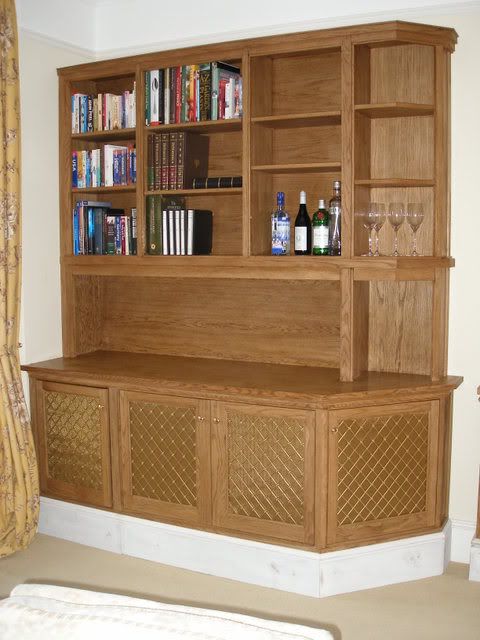

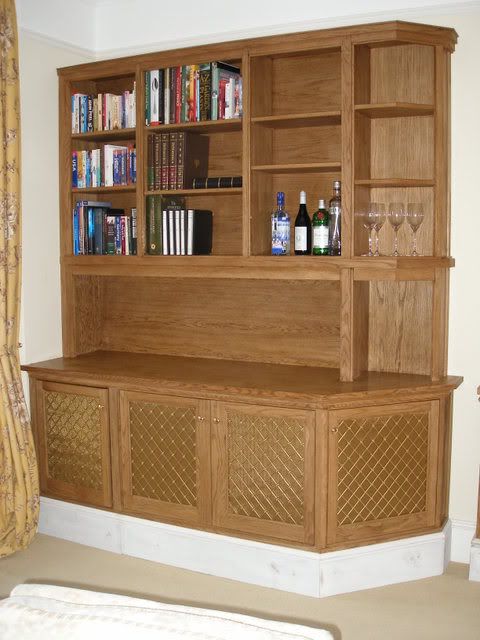

the following photo has walls that are 1/2 inch out in 9 feet right hand side and 3/8 left hand side but it all looks fully square

the costomers love it as well

second fix carpentry (trim) works on the same basis worldwide, it is a trick of the eye

a shaddow or reveal (that causes a shaddow) hides discrepancies by tricking the eye to see something else

but it is another way for second fix carpenters to "see / deal " with a problem

i work in english buildings of ages between 50 and 500 years old that have seen (and will continue to see) a lot of movement

since seeing the false joint tool in the uk festool catalog 2006 i have incorporated the technique into my reportiure

i have used a combination of scribing and 45 degree beveling (to create a shaddow gap) to good effect

the following photo has walls that are 1/2 inch out in 9 feet right hand side and 3/8 left hand side but it all looks fully square

the costomers love it as well

dirtydeeds

Member

- Joined

- Nov 22, 2007

- Messages

- 1,009

ps

the line you can see on the photo is the picture rail not the ceiling/wall junction

the line you can see on the photo is the picture rail not the ceiling/wall junction

I'll give you a great example of a shadow line that you can see anywhere you live. Go into an office building with a drop ceiling. They're greatly exaggerated, but it's the same sort of idea. When you trim the tile for the edge, you cut the tile so it hangs off that metal strip, which gives the eye a clean edge to reference.

i can not see them in this picture..i am not trying to be difficult,it just seems like if this were done one the floor it would highlight the problem. i understand how molding fools the eye but a sharp line?i accept that it works and if i see pictures showing it, i will feel like an idiot for asking these questions. thank you for the photo but i think i need another pic. again thanks

Michael Kellough

Member

dirtydeeds said:ps

the line you can see on the photo is the picture rail not the ceiling/wall junction

Nice work. I see the picture rail but not the false joint line, or the "shadow gap". We may be experiencing a clash of terminology here. I totally understand the need and process of scribing a cabinet to fit a wacky wall but where does the "shadow gap" come in?

Similar threads

- Replies

- 6

- Views

- 255

- Replies

- 35

- Views

- 6K

- Replies

- 1

- Views

- 541

- Replies

- 3

- Views

- 451