After spending possibly way more time than i should have, i modified both the vertical and horizontal cutting setups.

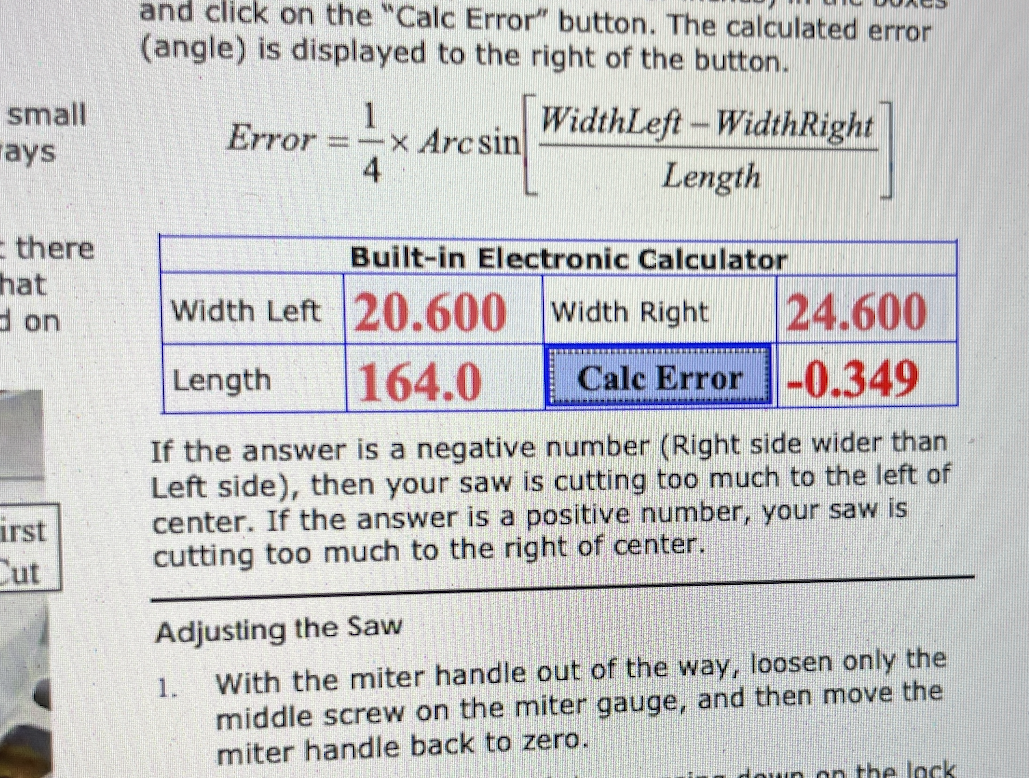

Horizontally using the 4 cut method in the manual, the result was .06° out.

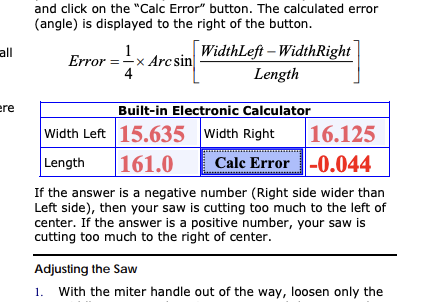

By the time I stopped stuffing around going backwards and forwards, I got it down to .01° ( from .8mm difference end to end down to .1mm) and called it.

Vertically, i was wrong in my above post, i was only out .2 degree using the digital angle box i have at home, both left and right side of the blade 89.8 and 90.2, same at 45°

I possibly made it more difficult than it need to be, but got it to 90 even eventually, still need to torque the nuts back up properly though.

As for the lasers, after I really really looked at them with a test groove cut etc they were fine and didn't need any adjusting.

Took I think around 3 hours all up.

Horizontally using the 4 cut method in the manual, the result was .06° out.

By the time I stopped stuffing around going backwards and forwards, I got it down to .01° ( from .8mm difference end to end down to .1mm) and called it.

Vertically, i was wrong in my above post, i was only out .2 degree using the digital angle box i have at home, both left and right side of the blade 89.8 and 90.2, same at 45°

I possibly made it more difficult than it need to be, but got it to 90 even eventually, still need to torque the nuts back up properly though.

As for the lasers, after I really really looked at them with a test groove cut etc they were fine and didn't need any adjusting.

Took I think around 3 hours all up.