sebr023

Member

Hi guys!

Don’t know if I post in the right place.

But I’m planning on building a helping/learning tower for my kid.

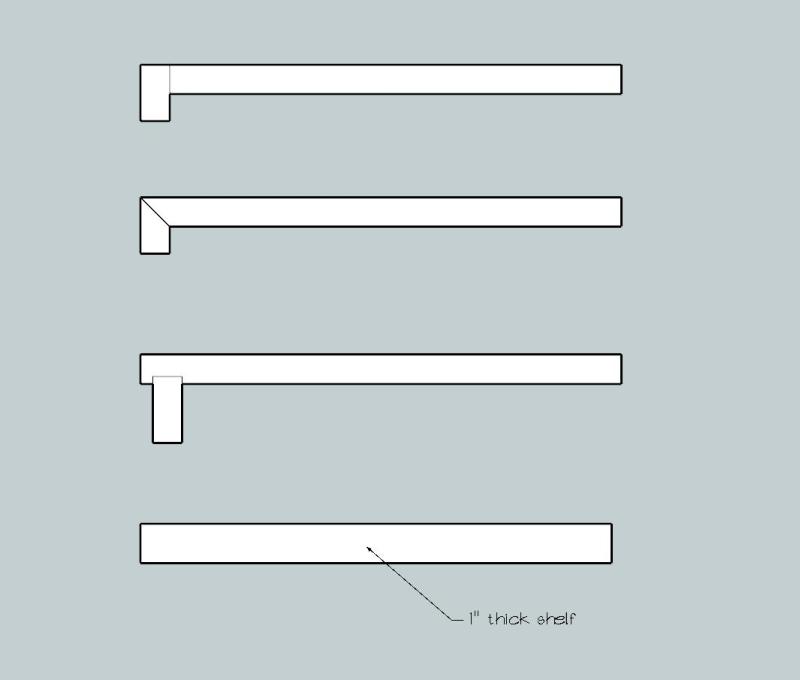

I will be laser cutting 1/4in Baltic birch plywood and laminating it to make a 1/2in. Having the outer plywood bigger by 2mm to be able to flush trim it. Also using 3/4-1” dowel to align both, and using it as a “design” element.

Almost all the design I see out there and the design I use to draw mine, seems to have adjustable heights.

My first question is:

If having adjustable height would make the structure weaker? Should I put more bracing?

Would having my kid standing on the “shelf” make the 1/2in plywood bend/flex in the middle?

Second question:

If having adjustable height is still a good idea.

I was thinking of having some ways to secure the step and the shelf in place.

I was thinking about 1/4 dowel, screws, or having them protrude on each side and it a wedge to lock them in place.

Aesthetic is important.

If using screws I would probably paint them the same colour as the outermost plywood layer for making them disappear. If going with screws, I’d use flathead hex 10-24 and insert hen in plywood? But seems a bit thin for 1/4 inch plywood. So maybe button head hex screws.

I don’t know how I would make dowel “easily removable” for when you want to adjust height. And having them aesthetically pleasing.

So yeah, I’d like to have your input on this simple design.

Sent from my iPhone using Tapatalk

Don’t know if I post in the right place.

But I’m planning on building a helping/learning tower for my kid.

I will be laser cutting 1/4in Baltic birch plywood and laminating it to make a 1/2in. Having the outer plywood bigger by 2mm to be able to flush trim it. Also using 3/4-1” dowel to align both, and using it as a “design” element.

Almost all the design I see out there and the design I use to draw mine, seems to have adjustable heights.

My first question is:

If having adjustable height would make the structure weaker? Should I put more bracing?

Would having my kid standing on the “shelf” make the 1/2in plywood bend/flex in the middle?

Second question:

If having adjustable height is still a good idea.

I was thinking of having some ways to secure the step and the shelf in place.

I was thinking about 1/4 dowel, screws, or having them protrude on each side and it a wedge to lock them in place.

Aesthetic is important.

If using screws I would probably paint them the same colour as the outermost plywood layer for making them disappear. If going with screws, I’d use flathead hex 10-24 and insert hen in plywood? But seems a bit thin for 1/4 inch plywood. So maybe button head hex screws.

I don’t know how I would make dowel “easily removable” for when you want to adjust height. And having them aesthetically pleasing.

So yeah, I’d like to have your input on this simple design.

Sent from my iPhone using Tapatalk