Deansocial

Member

- Joined

- Mar 14, 2010

- Messages

- 2,109

Deansocial said:Thats why i said for what i use it for

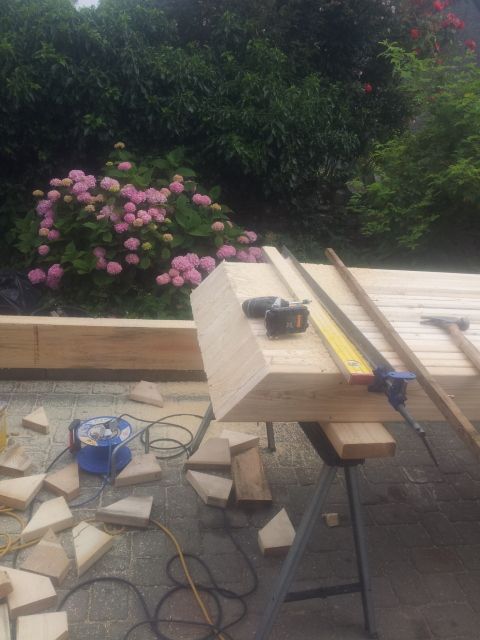

Deansocial said:Well i used jmbs sword saw today, my conclusion is that he needs to buy a cross cutting chain and the the bar imho is a little short for what we used it for but dont think the saw could handle much more. Also using it to gang cut rafters it tilts the wrong way as it sits on the offcut whcich means your cut starts to twist as you go along. Fine piece of kit but dont think i could invest that amount of money into it the way it is fordoing what i want to do with it.

leecab said:I have the 200mm sword saw.

The bar is not getting lubrication. That is despite the bar being clean and the 2 holes are not clogged. The oil pump is working as oil flows out.

The oil flows around the bar face and inside and around the plastic support surface, but wont go into the bar holes as the chain is always dry.

Yes I tested the red knob that selects oil 1,2 and full position.

Im using standard bar oil, even tried thinning it with kero.

NOTHING WORKS!!!

What is there left to consider anyone???

leecab said:I have the 200mm sword saw.

The bar is not getting lubrication. That is despite the bar being clean and the 2 holes are not clogged. The oil pump is working as oil flows out.

The oil flows around the bar face and inside and around the plastic support surface, but wont go into the bar holes as the chain is always dry.

Yes I tested the red knob that selects oil 1,2 and full position.

Im using standard bar oil, even tried thinning it with kero.

NOTHING WORKS!!!

What is there left to consider anyone???

leecab said:I have the 200mm sword saw.

The bar is not getting lubrication. That is despite the bar being clean and the 2 holes are not clogged. The oil pump is working as oil flows out.

The oil flows around the bar face and inside and around the plastic support surface, but wont go into the bar holes as the chain is always dry.

Yes I tested the red knob that selects oil 1,2 and full position.

Im using standard bar oil, even tried thinning it with kero.

NOTHING WORKS!!!

What is there left to consider anyone???

leecab said:leecab said:I have the 200mm sword saw.

The bar is not getting lubrication. That is despite the bar being clean and the 2 holes are not clogged. The oil pump is working as oil flows out.

The oil flows around the bar face and inside and around the plastic support surface, but wont go into the bar holes as the chain is always dry.

Yes I tested the red knob that selects oil 1,2 and full position.

Im using standard bar oil, even tried thinning it with kero.

NOTHING WORKS!!!

What is there left to consider anyone???leecab said:I have the 200mm sword saw.

The bar is not getting lubrication. That is despite the bar being clean and the 2 holes are not clogged. The oil pump is working as oil flows out.

The oil flows around the bar face and inside and around the plastic support surface, but wont go into the bar holes as the chain is always dry.

Yes I tested the red knob that selects oil 1,2 and full position.

Im using standard bar oil, even tried thinning it with kero.

NOTHING WORKS!!!

What is there left to consider anyone???leecab said:I have the 200mm sword saw.

The bar is not getting lubrication. That is despite the bar being clean and the 2 holes are not clogged. The oil pump is working as oil flows out.

The oil flows around the bar face and inside and around the plastic support surface, but wont go into the bar holes as the chain is always dry.

Yes I tested the red knob that selects oil 1,2 and full position.

Im using standard bar oil, even tried thinning it with kero.

NOTHING WORKS!!!

What is there left to consider anyone???

Cheese said:I just wish the sword saw was around 20 years ago...I decided to stuff the insulation cavities with multiple layers of foam board and at the time not much else was available other than fiberglas.

It was a long and slow process because each foam insert had to be cut individually as ganging the items was not an option. I had to manufacture my own cutting tool at the time and each panel had to be cut individually.

If you're wondering...it was well worth the effort. [smile]