DeformedTree said:

Cutting out the nonsense, we know very much how wire sizing works here.

Yeah, well, you kinda have to because not knowing it will be a bigger risk in your system. In NL you can use one general rule for residential; all circuitbreakers 16A and all wiring 2,5mm^2.

DeformedTree said:

Again, you are getting hung up on trying to make them as small as you can or that buying/installing bigger gauge wire is some horrible burden.

Copper ain't free. That is why the core of your pennies is now Zinc.

DeformedTree said:

You also keep forgetting that for most the stuff you are talking about we are 240V, no change in wire size happens as it's all ready the same voltage (higher actually). We are powering stuff that is 240V and big amps. We use 240V for the same reason, it reduces amps, but what we are powering is much more powerful. 120V is used for lights and plugs, the stuff wired with 12 and 14 gauge wire, just like how you guys have 2 size wires for lights and plugs.

Hehe lol. On that two sizes for lights; Since 1968 when we adopted the European wire color standard we had the rule that switches wires had to be black or gray. Since the only switched thing in a home is lights and 1.5mm^2 was allowed for that it became logic to buy the black wire in 1,5mm^2. That rule might change, also allowing brown, but black 1.5mm^2 will probably still persist because if you are pulling wire you still need the extra roll.

DeformedTree said:

We could say we use less than you since we tend to use romex, so we aren't buying individual wires in different colors, but that's just getting silly. A spool of 12/2 and a spool of 14/2 and you are good to go for almost the entire house.

Almost... so not really. Did you see the Youtube clip of the wire Systainer?

DeformedTree said:

When we are using 10, 8, 6 gauge wire, it's 240V applications. We also do use the 12 and 14 for 240V stuff too (common for base board heat). There is no magical change in wire size.

You brought up the list of wire sizes, not me.

DeformedTree said:

And sizing wire is about the rise in temp of the wire due to it's insulation. We aren't constraining ourselves to 110V, we use it where the need for 240V is almost non-existant, and the safety benefit of lower voltage wins out. Sure, 240V makes it easier to run a large router in the living room, not going to sell folks on getting rid of 120V.

You actually are constraining yourself, just like with the imperial system, but keep making excuses not to change. And I get it; change is hard. That is why the UK is stuck with the most lousy rail loading gauge while the US could learn from the UK's mistake and has way bigger loading gauge. In some sense you could say Europe learned from the 110V mistake in the US.

DeformedTree said:

Big loads are 240V, somehow the seams to keep getting missed. If someone has oven, furnace, etc and it is 240V/60A, folks don't want to run 4 separate 15A runs to it.

Neither do we. We run a single 3-phase circuit. 5x2,5mm^2 in 19mm conduit, good for 11 kW. Specific for NL we cheated and have a handicapped version (for homes with single-phase connection) where we run 2 single circuits in parallel for 7,4 kW. I actually just installed one in my brother's home a week ago. Now he has a 7,4 kW induction cooktop.

DeformedTree said:

We go parallel when we have loads over 100A because you hit a limit of the breakers. So you have to start splitting it up, but that just isn't common, and when you can just grab the right size wire and be done with it, there is no issue.

So many how different types of wire does the residential service electrician have in his van?

DeformedTree said:

You don't have wide spread use of large electrical appliances in homes there. Not everything is easy to break up the loads. An electric car charger wants 240V/50A, not 3Phases.

Really? The Tesla's here are charged with 3-phase. There are some single phase 32A cars, these are annoying for the typical NL home installation.

DeformedTree said:

That just means you will have to add more electronics to the charger to get it to something the car accepts.

Yeah, because one tiny part of the globe sticks to a standard from 2 centuries ago

DeformedTree said:

Same for other devices. And it's not like the runs with 10, 8, 6AWG are long. Most are short as there is only a couple of them going to the same places, like the kitchen, or utility room, all of which are close to the electrical panel. If someone has a small home, that is natural gas dependent, guess what? They might have only 12 and 14gauge wiring in the whole house. As they might not have electrical circuits for range/cooktop/oven/AC/furance/Hot Water Heater/etc. Problem is those houses will need to be upgraded in one form or another as gas service is eliminated.

We had mandatory 19mm conduit to the kitchen since ages. But I think they scrapped it a few years ago. But more recently new homes aren't even connected to the gas network and of 99% that don't have the empty conduit you go through the crawl space. That's the route used in my brother's home too, since his kitched moved from the original 1970's spot.

DeformedTree said:

I have nothing against 230/240V power. I'd be fine with us being all 240V power. But to act like there is something terrible wrong or problematic with 120V is silly. It works very well.

Yet all these topics complaining about the two gauge cords, the plugs on the CT, the power rating of the outlet on the CT etc. suggest otherwise.

DeformedTree said:

Same with 3 phase distribution, it's nice, works well if I have a lot of large motors to power. But it hardly changes anything in the big picture, power is power at the transmission level. Both systems work perfectly well. There is zero chance of the USA and all the other countries with the same system changing,

There are actually very few countries that use 110V

DeformedTree said:

there just is no economic reason for that change. There is no overall technical reason for going with one over the other. If the world was starting over, there would be debates on which way to go.

Maybe that has something to do with the time you see as reasonable to get a return on investment.

DeformedTree said:

What matters is the systems being able to handle the future, which is pure electric. The USA, Canada are well positioned as more of our homes are in a better position to handle the increased electrical demands as we put much bigger electrical services into our homes.

That just means more possibily to install wastefull ways of heating. Like resistive instead of heatpump. Or with too little insulation.

DeformedTree said:

Coen said:

DeformedTree said:

We use the right solutions for the problem. Safety rules all in US electrical.

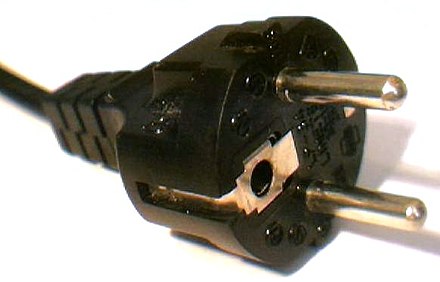

Aaaah! So that is why you cut off the notches of thinner gauge cords?

What does this mean?

Cutting off tabs of the ends of thinner cords is definitly not "Safety rules all".