You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for suggestions to hang a screen door

- Thread starter 4nthony

- Start date

luvmytoolz

Member

Or use a standard HSS drill with 5% cobalt, sets with cobalt are probably double the cost of a standard HSS set, but individual drills would be very cheap. Then it's just like drilling ferrous iron.luvmytoolz said:

You could also just get some hole-less butt hinges and drill where you want the holes?

4nthony said:

That's actually not a bad idea. I could even try and cut down the leaf on a larger hinge to fit the smaller door.

Just a heads-up...if the hole-less hinge is stainless, be careful of work hardening the metal when drilling the new holes.

I think we're going to need to see some photos of the results posted after all that.As much as I hate to do it, I think I'm just going to grab some smaller butt hinges, install a partial jamb on the hinge side (I've already got the piece milled up and waiting), trim the door to accommodate the extra width of the jamb, and mount it.

Packard

Member

I suspect that none of the options will work as well as the one designed for screen doors—the one at the outset you said you did not want to use. While most are black or white powder-coated, there are a few variations that you might find less objectionable.

The risk of pursuing this as you are, is that you find something that “works”, but really just hobbles along until it fails.

At any rate, take another look and see if there is a variation that you can live with:

The risk of pursuing this as you are, is that you find something that “works”, but really just hobbles along until it fails.

At any rate, take another look and see if there is a variation that you can live with:

4nthony

Member

I suspect that none of the options will work as well as the one designed for screen doors—the one at the outset you said you did not want to use. While most are black or white powder-coated, there are a few variations that you might find less objectionable.

The risk of pursuing this as you are, is that you find something that “works”, but really just hobbles along until it fails.

At any rate, take another look and see if there is a variation that you can live with:

I don't want surface mount as I'm not a fan of the way they look. As for the majority of butt hinges, they'll hit very near to the seam in the jamb/stucco and I also want to avoid drilling there. The other options I've been exploring are just ways around the hole locations.

I'm not averse to butt hinges. Roton hinges look great, but again, not sure they'll avoid the seam as I didn't see offset leafs.

The search continues

Last edited:

Packard

Member

Brass-Plated Drop Leaf Hinges for Shaped Edges

Need an affordable replacement for your worn-out table hinges? These brass-plated Drop Leaf Hinges for Shaped Edges provide an elegant appearance and smooth up-and-down action for table leaves that incorporate a rule joint.

There’s also these, bit more spendy though. https://www.jwwinco.com/en-us/produ...el-Heavy-Duty-Hinges-with-Extended-Hinge-Wing

Attachments

Cheese

Member

I might add, that it's imperative to use a M42 cobalt bit to drill stainless using a drill press. More important, is to make sure it's sharp. A dull cobalt drill bit will dwell in one spot longer and put heat into the stainless thus work hardening the surface. When drilling stainless you have to fully commit...you get in and make a cut and then get out. Any dawdling around just produces heat, dulls the drill bit and work hardens the surface.Or use a standard HSS drill with 5% cobalt, sets with cobalt are probably double the cost of a standard HSS set, but individual drills would be very cheap. Then it's just like drilling ferrous iron.

Many, many moons ago I drilled out stainless steel brake rotors for a motorcycle on a Bridgeport. My procedure was to have 6 each of the final size drill bit in M42 cobalt and lots of lubricant. That way I could drill about 12-18 holes before I had to resharpen the cobalt drill bits.

Last edited:

Packard

Member

Instead of stainless, maybe plated brass hinges. Chrome plated, or preferably nickel plated brass.

Brass is a proven material for hinges and drills easily. Nickel plating is less likely to chip. The main advantage of chrome plating is its resistance to scratching (chrome is very hard). Nickel has superior adhesion in electro-plating.

At any rate, I would expect any stainless steel hinge will also be available in solid brass.

Brass is easily drilled.

Brass is a proven material for hinges and drills easily. Nickel plating is less likely to chip. The main advantage of chrome plating is its resistance to scratching (chrome is very hard). Nickel has superior adhesion in electro-plating.

At any rate, I would expect any stainless steel hinge will also be available in solid brass.

Brass is easily drilled.

luvmytoolz

Member

Absolutely, M42 can be too brittle to use in a hand drill, M35 would be better there.I might add, that it's imperative to use a M42 cobalt bit to drill stainless using a drill press.

4nthony

Member

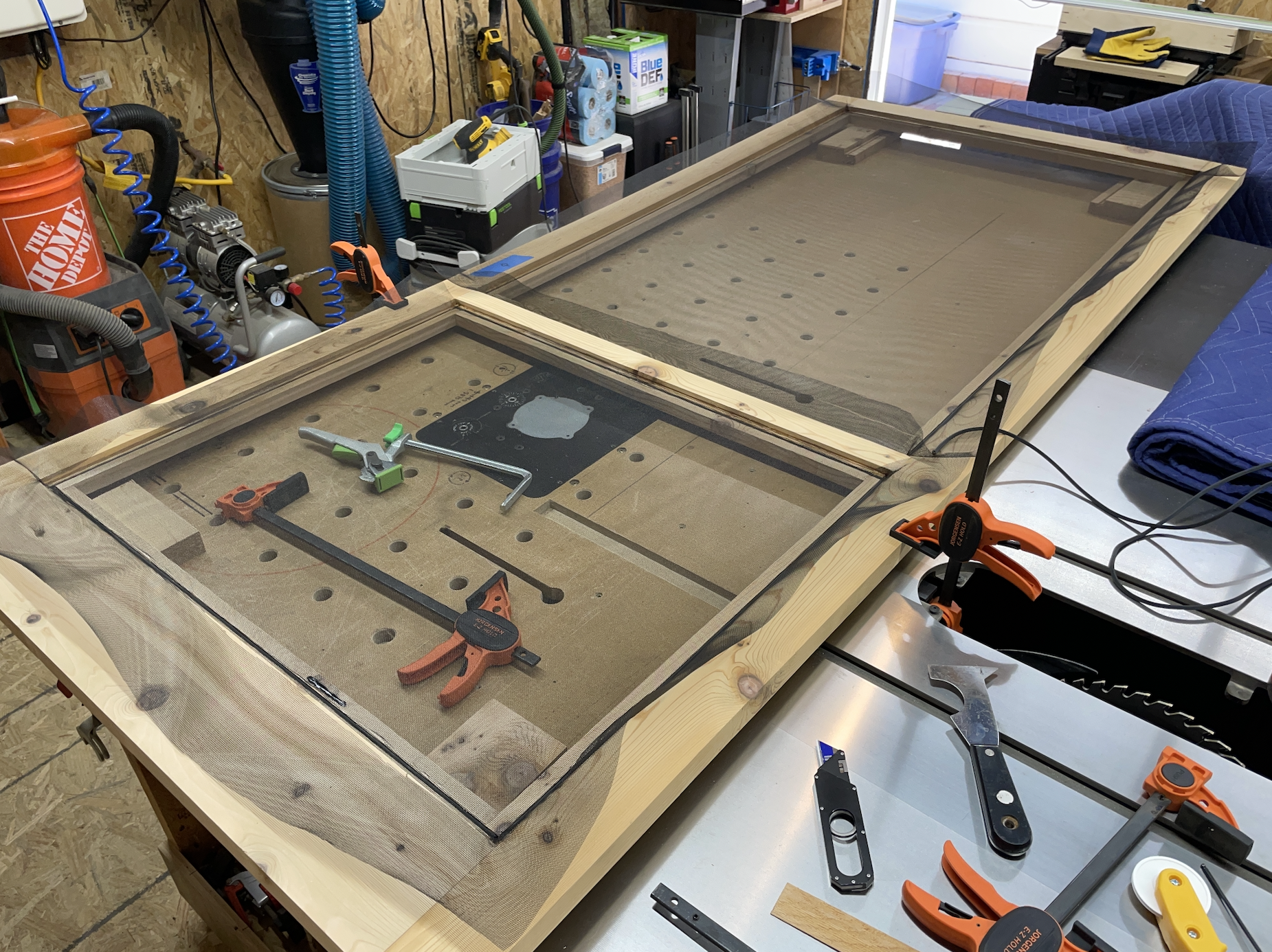

After all that, I went back to my original plan and cut 18 mm off the hinge side of the door to accommodate a partial jamb. I'm heading up to the house tomorrow to install it. Just need to attach the faux jamb and trim the other side to fit.

I'll use a few trim head screws to attach it to the existing jamb.

I appreciate all the great ideas presented to me, thanks everyone.

I'll use a few trim head screws to attach it to the existing jamb.

I appreciate all the great ideas presented to me, thanks everyone.

luvmytoolz

Member

Looks great Anthony!

If I could make one small suggestion, run a shallow vee groove on the other stile to match the faux jamb?

If I could make one small suggestion, run a shallow vee groove on the other stile to match the faux jamb?

4nthony

Member

Looks great Anthony!

If I could make one small suggestion, run a shallow vee groove on the other stile to match the faux jamb?

Great idea!

I don’t think I have a vee router bit but after I trim the door to size, I can create a thin shadow line with the track saw to balance it out.

Packard

Member

What moulding are you using for the screen? Wood or anodized aluminum? I used the aluminum moulding and the aluminum clip that allows for a mitered corner. I tried the plunger retainer but it was too much of a hassle. I went with the turn buttons.

My screen door to the garage was not for insects but to keep the raccoons out and allow ventilation.

The front door screen was more for appearance as I never leave the front door open. The whole house attic fan is most effective when only a few windows are open. If a lot of windows are open, then the air flow through each is diminished.

My screen door to the garage was not for insects but to keep the raccoons out and allow ventilation.

The front door screen was more for appearance as I never leave the front door open. The whole house attic fan is most effective when only a few windows are open. If a lot of windows are open, then the air flow through each is diminished.

4nthony

Member

I attached the screen with spline and used cedar offcuts for the moulding. I wanted the screen to be as taut as possible and had a small area that tore when the spline went in. I was able to mend it with some CA glue.What moulding are you using for the screen? Wood or anodized aluminum?

I used pin nails to attach the moulding. If I need to replace the screen, they should pop off with a little force giving me access to the spline.

Some photos from the install. It turned out decent and the tenants were stoked so win-win. I wanted to put the groove/shadow line on the handle side as suggested by @luvmytoolz but completely forgot about once the door had been trimmed to size.

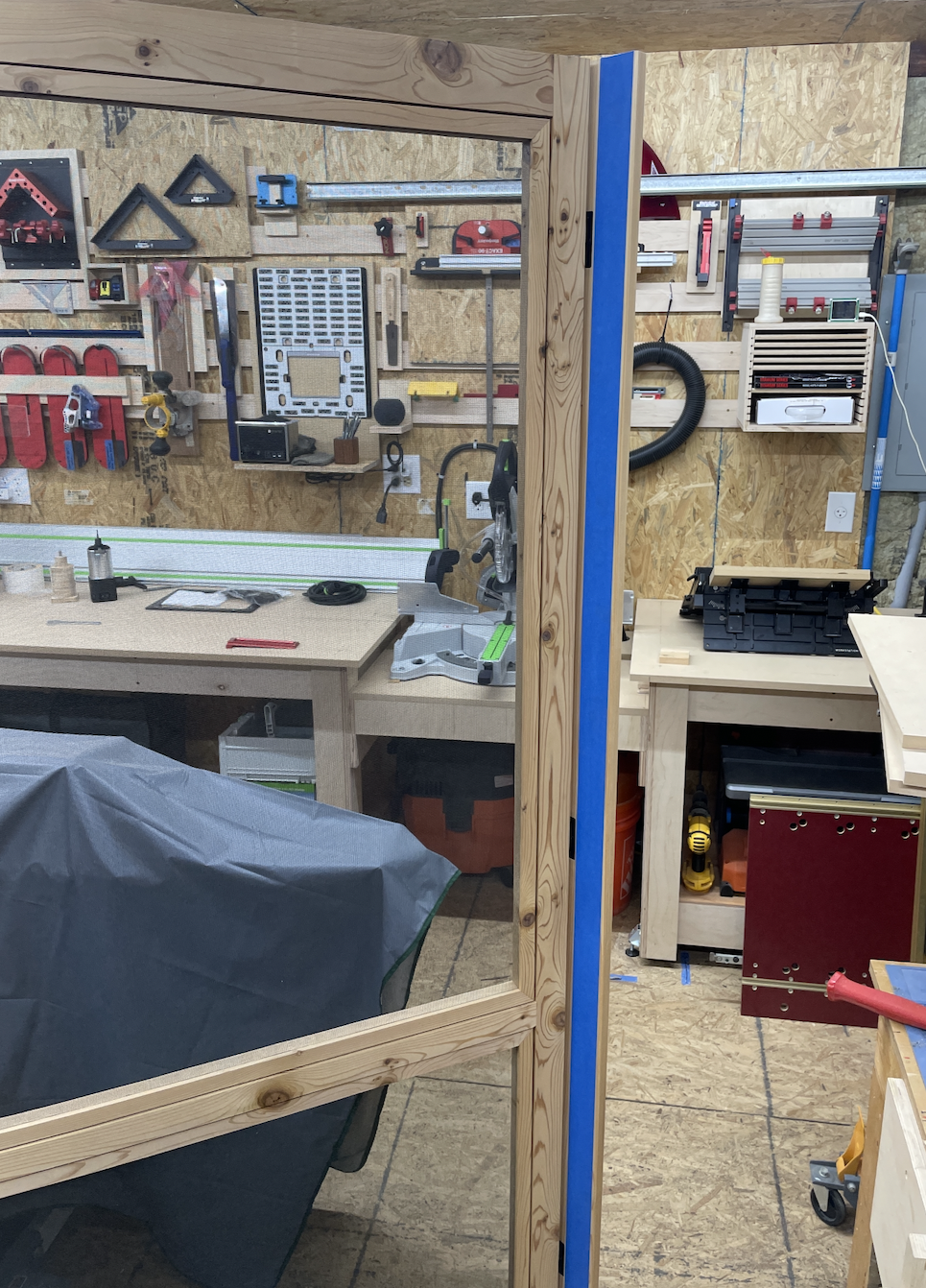

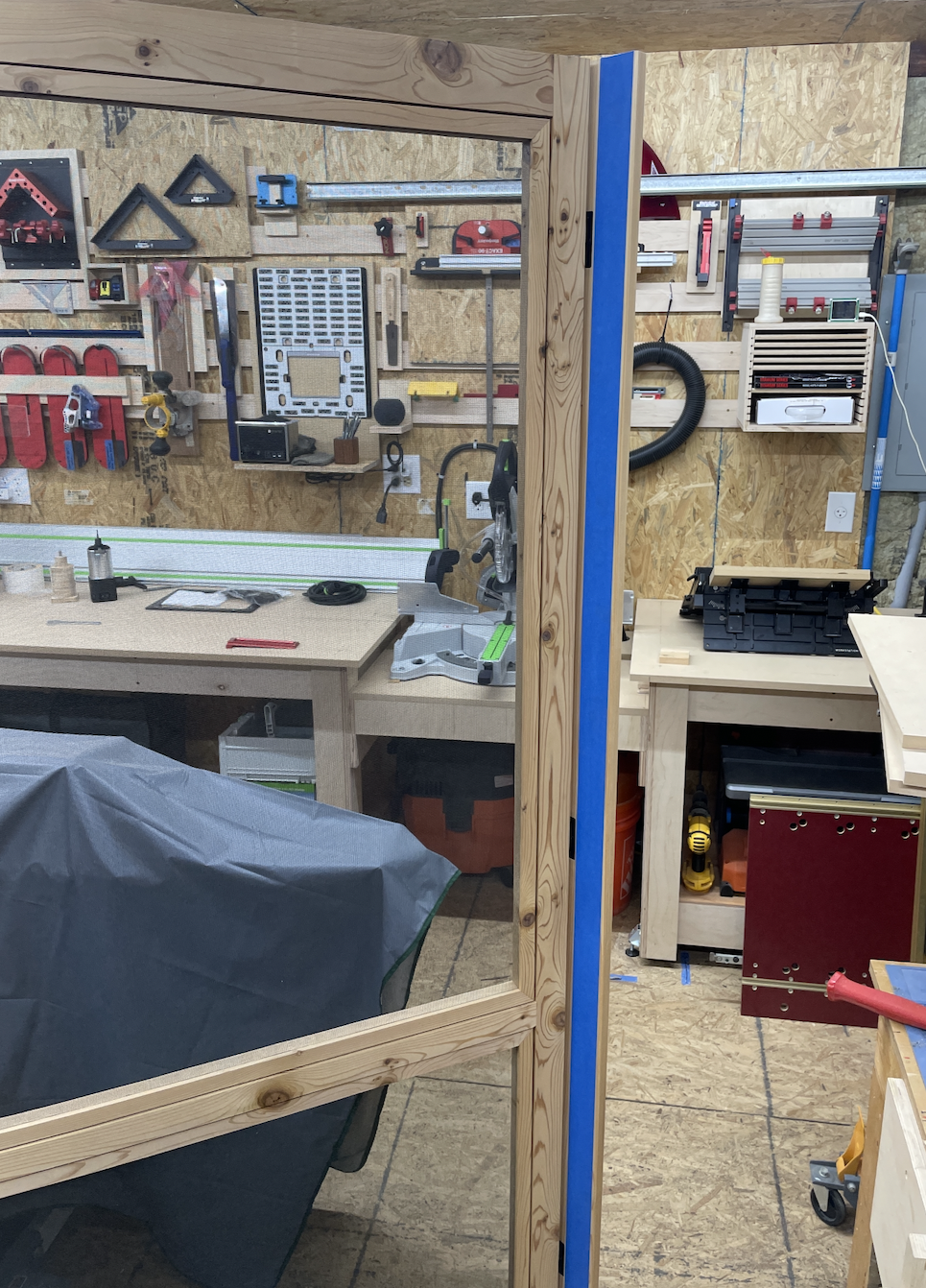

The faux jamb:

The jamb from the inside:

One of the offcuts from trimming down the door to accommodate the faux jamb ended up being perfect to use as a trim stop.

This was fun. My first time building and hanging a screen door. Though, it definitely won't be my last time overthinking how to accomplish a task.

Thanks again for all the feedback.

Cheers,

Anthony

luvmytoolz

Member

Nice work Anthony, looks great. I love the look of cedar, such a beautiful timber.

Similar threads

- Replies

- 15

- Views

- 966

- Replies

- 8

- Views

- 1K

- Replies

- 28

- Views

- 896